custom concrete color pigments manufacturers

Understanding Custom Concrete Color Pigments A Comprehensive Guide to Manufacturers

Concrete, a versatile and durable construction material, is increasingly being used in a variety of applications ranging from residential homes to commercial buildings. One of the most exciting advancements in concrete technology has been the development of custom concrete color pigments. These pigments allow architects and designers greater creativity and flexibility in their projects, enabling them to achieve vibrant colors and unique finishes. In this article, we will explore custom concrete color pigments, their benefits, and the role of manufacturers in this evolving industry.

The Importance of Color in Concrete

Traditionally, concrete has been associated with a bland gray color. However, as aesthetic preferences have evolved, so too has the demand for colored concrete. Custom color pigments are essential in this transformation, as they provide not just color, but also depth and character to concrete surfaces. From residential patios to commercial entries, colored concrete can significantly enhance visual appeal and provide a distinctive look to any space.

Types of Custom Concrete Color Pigments

1. Synthetic Color Pigments These are man-made dyes and pigments that produce consistent colors. They offer a wide range of hues and are highly durable, ensuring that the color remains vibrant over time. Synthetic pigments are often preferred for their performance and reliability.

2. Natural Color Pigments Derived from natural materials, these pigments offer earthy tones and are often used in eco-friendly projects. While they may not provide the same level of vibrancy as synthetic pigments, they are popular for their organic appeal.

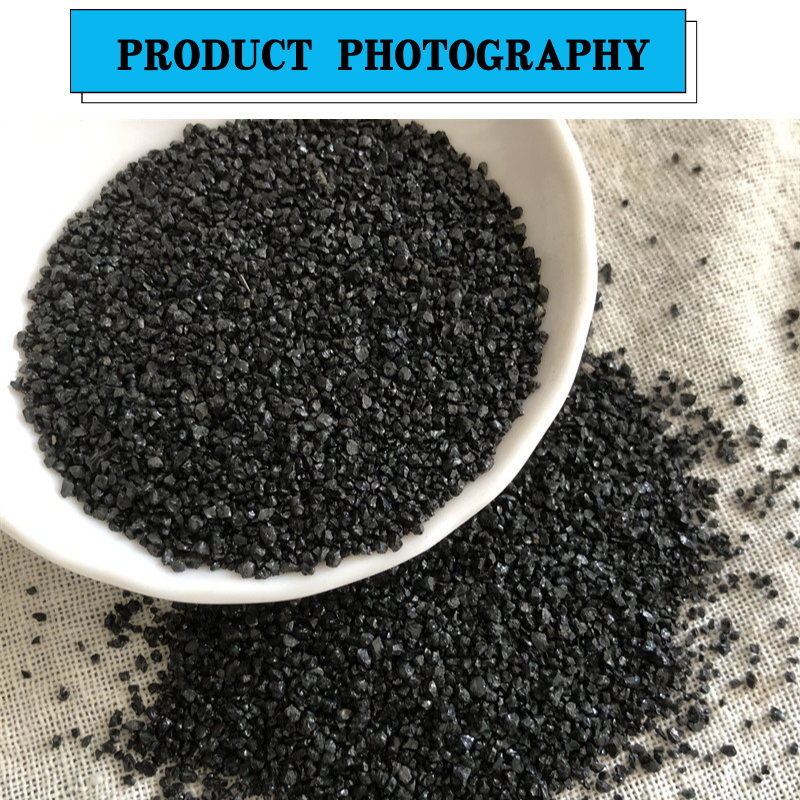

3. Iron Oxide Pigments These are widely used in the concrete industry due to their stability and UV resistance. Iron oxide pigments come in various colors, including reds, yellows, and blacks, allowing for a broad spectrum of design possibilities.

4. Custom-Blended Pigments Many manufacturers offer custom blending services, allowing contractors and designers to create unique colors that meet specific project requirements. This custom approach fosters creativity and enables the realization of a designer's vision.

Benefits of Using Custom Concrete Color Pigments

1. Aesthetic Appeal The primary benefit of custom concrete color pigments is the enhanced visual appeal they provide. By introducing color to concrete, architects and designers can create more inviting and dynamic environments.

custom concrete color pigments manufacturers

2. Durability High-quality pigments are formulated to withstand harsh weather conditions and UV exposure, ensuring that the color remains intact over time. This durability minimizes the need for repairs or repainting, ultimately saving costs in the long run.

3. Versatility Custom-colored concrete can be used in various applications, including sidewalks, driveways, walls, and decorative elements. The ability to customize colors means that any style or theme can be achieved, from modern to rustic.

4. Environmental Considerations Many manufacturers are increasingly focusing on sustainable practices, producing pigments that are eco-friendly. This is appealing for projects that prioritize green building practices.

The Role of Manufacturers in Custom Concrete Color Pigments

Manufacturers play a crucial role in the development and distribution of custom concrete color pigments. They are responsible for

1. Research and Development Continuous R&D ensures that manufacturers can keep up with industry trends and technological advancements. New formulations that improve color consistency, durability, and environmental impact are regularly introduced.

2. Quality Control Reliable manufacturers implement stringent quality control measures to ensure that their pigments meet industry standards. This is vital for contractors who rely on these materials to deliver high-quality projects.

3. Customer Support Leading manufacturers provide technical support and guidance to help contractors and designers select the right pigments for their projects. This support can significantly impact the final outcome, ensuring success in the color application process.

4. Education and Training Many manufacturers offer educational resources and training sessions for their customers. This helps contractors understand the best practices for using color pigments and achieving optimal results in their concrete applications.

Conclusion

Custom concrete color pigments have revolutionized the concrete industry, providing endless possibilities for aesthetics and design. As manufacturers continue to innovate and prioritize quality, the use of color in concrete will only expand, leading to more beautiful and functional spaces. Whether for residential, commercial, or artistic applications, custom concrete color pigments will remain a critical component in the evolution of concrete design. For architects and contractors alike, understanding the options available and the significance of quality manufacturers will be key to achieving outstanding results in their projects.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025