Custom Activated Carbon Powder Manufacturing Facilities and Their Benefits for Various Industries

The Rise of Custom Activated Carbon Powder Factories A Shift Toward Tailored Solutions

In recent years, the demand for activated carbon has seen a significant surge, fueled by its diverse applications across various industries. From water treatment to air purification, the effectiveness of activated carbon in adsorption processes makes it a highly sought-after material. As businesses seek to optimize their operations and address specific requirements, the emergence of custom activated carbon powder factories has become a prominent trend.

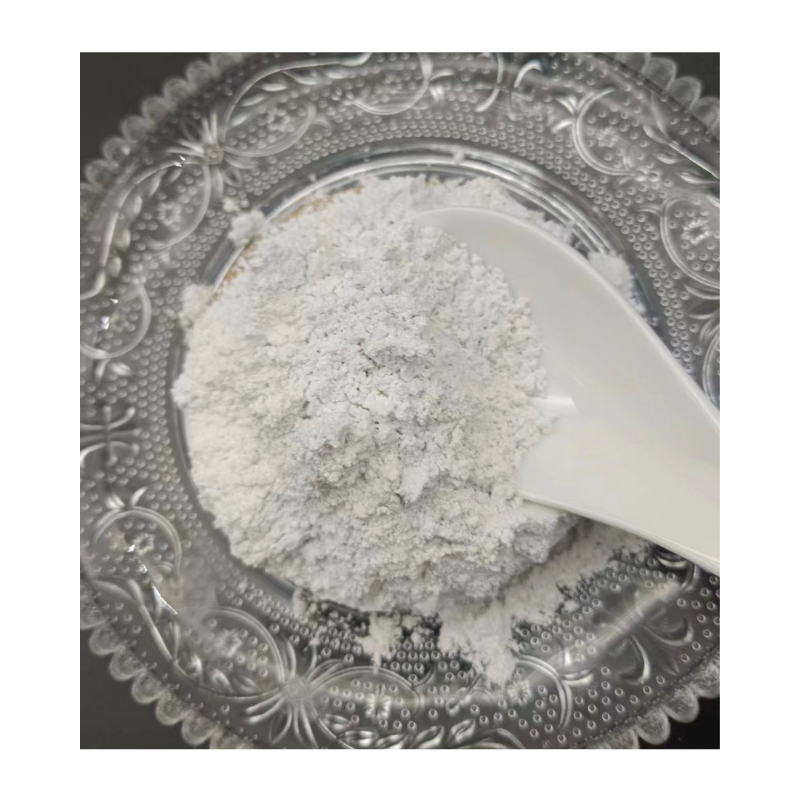

Activated carbon, known for its high surface area and porosity, is derived from carbonaceous materials such as wood, coal, or coconut shells. It plays a critical role in the removal of impurities and contaminants, whether from air, water, or industrial processes. While standard grades of activated carbon are available in the market, the unique characteristics of many applications often necessitate customized solutions. This is where custom activated carbon powder factories step in, offering tailored products designed to meet specific industry needs.

One of the primary advantages of custom activated carbon is its ability to enhance performance. Different applications may require variations in particle size, pore structure, and adsorption capacity. For instance, a factory specializing in water filtration may focus on producing activated carbon with a larger pore size to effectively remove larger contaminants, while another dedicated to air purification may prioritize smaller particles to capture volatile organic compounds (VOCs). By offering customized products, these factories ensure that their clients achieve optimal results.

Moreover, custom activated carbon powder factories are becoming increasingly adept at utilizing advanced technologies and innovative manufacturing processes. With the integration of machine learning and data analytics, these factories can efficiently analyze client requirements and adjust production parameters to create tailored products. This level of responsiveness not only improves product quality but also accelerates delivery times, allowing businesses to keep pace with the rapid shifts in market demands.

custom activated carbon powder factories

Sustainability is also a significant driving force behind the growth of custom activated carbon powder factories. As environmental regulations become more stringent and consumers demand eco-friendly products, the emphasis on sustainable sourcing and production practices has intensified. Many factories are focusing on utilizing renewable resources and waste materials, such as agricultural byproducts, to produce activated carbon. This not only reduces waste but also lowers the carbon footprint associated with traditional production methods.

In addition, collaboration between manufacturers and clients is key to the success of custom activated carbon solutions. By engaging in a thorough dialogue, factories can gain valuable insights into specific challenges faced by different industries. This partnership model fosters innovation, leading to the development of cutting-edge activated carbon products that are designed to tackle emerging issues. For instance, industries faced with new contaminants in wastewater can work directly with manufacturers to create customized solutions that effectively address these challenges.

Furthermore, the competitive landscape has evolved, encouraging factories to offer added value beyond just the product. Many custom activated carbon powder manufacturers are now providing consultation services, helping clients optimize their applications by selecting the most suitable product and configuration. This holistic approach caters to the growing need for support and expertise in implementing activated carbon solutions.

In conclusion, the emergence of custom activated carbon powder factories represents a significant advancement in the materials industry. These factories not only cater to the specific needs of various sectors but also contribute to sustainability and innovation. As the demand for specialized activated carbon continues to grow, it is clear that custom solutions will play a crucial role in shaping the future of environmental protection and industrial efficiency. By focusing on tailored approaches, manufacturers can help businesses navigate the complexities of modern challenges, paving the way for a cleaner and more sustainable future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025