custom 100 calcium bentonite clay factories

The Importance of Custom 100 Calcium Bentonite Clay Factories

Calcium bentonite clay is a type of absorbent clay that has gained prominence in various industries due to its unique properties and versatility. Commonly formed from the weathering of volcanic ash in the presence of water, this natural material is rich in minerals and has a myriad of applications ranging from agriculture to industrial uses. Custom 100 calcium bentonite clay factories play a pivotal role in tailoring this resource to meet specific needs, thus enhancing its value across various sectors.

Understanding Calcium Bentonite Clay

Calcium bentonite is characterized by its swelling properties and high cation exchange capacity. These features make it an excellent adsorbent, allowing it to bind with toxins, pollutants, and heavy metals. Its natural absorbency makes it an essential component in various applications such as drilling fluids, cosmetics, pharmaceuticals, and as a feed additive in animal agriculture. Additionally, calcium bentonite clay is utilized in construction materials and environmental remediation projects due to its effective sealing and barrier properties.

The Role of Custom 100 Factories

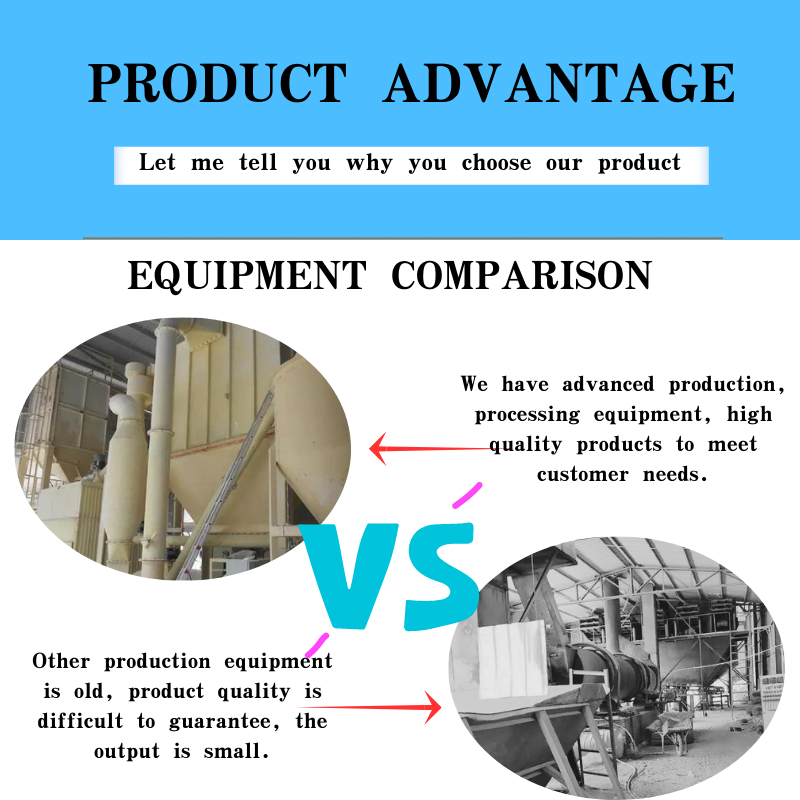

Custom 100 calcium bentonite clay factories are specialized facilities that focus on creating tailored products suited for specific applications. The 100 in the designation refers to the purity and quality standard that these factories adhere to, ensuring that the bentonite clay produced meets the highest industry standards.

1. Customization for Specific Applications Each sector requiring calcium bentonite has distinct needs. For instance, the agriculture industry might seek clay that promotes soil health and enhances water retention, while the cosmetics industry will focus on clays that are milled to a fine powder for smoother texture and better absorption. Custom factories excel in meeting these diverse requirements, providing tailored solutions that improve product performance.

custom 100 calcium bentonite clay factories

2. Quality Control and Assurance One of the primary advantages of custom 100 factories is the rigorous quality control process they implement. This ensures that the end product is not only effective but also safe for use in sensitive environments such as food production and personal care. High standards of quality assurance help minimize contaminants and guarantee the consistency of the bentonite clay being produced.

3. Innovation and Research Custom factories often engage in research and development to further enhance the qualities of calcium bentonite clay. By experimenting with processing techniques and combining it with other materials, they can create innovative products that meet the evolving needs of industries. For instance, modifications in the clay's particle size or activating it through chemical processes can significantly enhance its functionalities.

Economic Impacts of Custom 100 Calcium Bentonite Clay Factories

The establishment of custom calcium bentonite factories not only meets the direct needs of various industries but also contributes significantly to local economies. They create jobs in manufacturing, distribution, and research, fostering economic development in the regions where they operate. Furthermore, as demand grows for sustainable and eco-friendly materials, these factories position themselves as key players in promoting environmentally responsible solutions.

Conclusion

Custom 100 calcium bentonite clay factories are essential players in the global economic landscape. They not only transform raw natural resources into high-value products tailored for specific applications but also ensure quality and compliance with industry standards. As industries continue to seek innovative and efficient solutions, the role of these factories will only grow, paving the way for advancements in multiple sectors, including agriculture, construction, and environmental management. By highlighting the significance of custom bentonite clay production, we recognize the intricate relationship between industry needs and the continuous evolution of natural resources to meet them. In this context, those engaged in the operation and development of these factories are not merely manufacturers—they are vital contributors to a sustainable future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025