custom silica fume powder

Understanding Custom Silica Fume Powder Properties, Applications, and Benefits

Silica fume, a byproduct of silicon and ferrosilicon metal production, has gained significant attention in the construction and materials industry due to its unique properties and advantages. Custom silica fume powder refers to tailor-made silica fume that is optimized for specific applications, enhancing the performance of construction materials and contributing to sustainable building practices.

Properties of Silica Fume Powder

Silica fume is composed of very fine particles, typically less than 1 micron in diameter, which gives it a large surface area – over 20 times that of cement. This fine particle size contributes to its high pozzolanic activity, meaning it can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The chemical composition primarily consists of silica (SiO2), typically over 90%, along with trace amounts of other compounds like aluminum oxide (Al2O3) and iron oxide (Fe2O3).

The high specific surface area of custom silica fume makes it ideal for improving the mechanical properties of concrete. When added to concrete mixes, it enhances strength, durability, and workability. Additionally, silica fume reduces permeability, which helps in preventing corrosion of steel reinforcement bars and improving the overall lifespan of concrete structures.

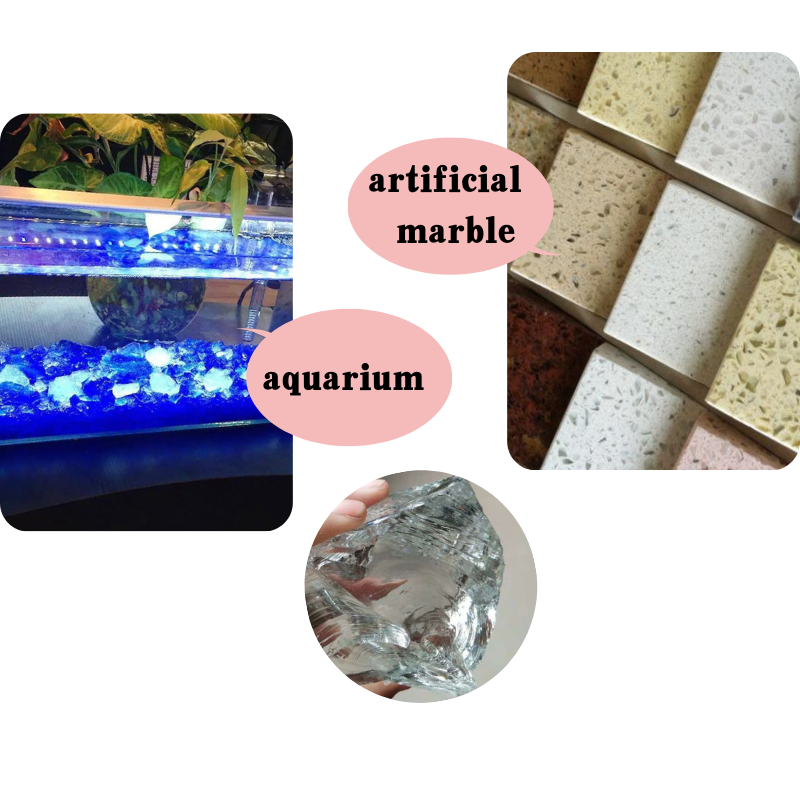

Applications of Custom Silica Fume Powder

1. Concrete Production Custom silica fume is widely used in high-performance concrete formulations. Its incorporation leads to increased compressive and flexural strength, making it suitable for a range of structural applications, from bridges to high-rise buildings.

2. Self-Consolidating Concrete (SCC) Silica fume aids in the development of self-consolidating concrete, which flows easily and fills formwork without the need for vibration. This characteristic is particularly beneficial for complex shapes and densely reinforced structures.

custom silica fume powder

4. Waterproofing and Durability Its fine particles fill voids in the concrete matrix, significantly reducing porosity and enhancing the material’s resistance to water ingress and chemical attack. This makes it an excellent choice for applications in harsh environments, such as marine structures and sewage treatment plants.

5. Industrial Flooring Custom silica fume is also utilized in industrial flooring systems where high durability and resistance to wear are required. The addition of silica fume improves the density and hardness of the flooring, enhancing its performance under heavy loads.

Benefits of Using Custom Silica Fume Powder

1. Enhanced Strength One of the most significant benefits of custom silica fume is the increase in compressive and flexural strength of concrete. High strength is crucial for structural integrity, particularly in demanding applications.

2. Sustainability As a byproduct of industrial processes, silica fume contributes to eco-friendly construction practices. Its use in concrete reduces the need for cement, thus lowering carbon emissions associated with cement production.

3. Versatility The ability to customize silica fume according to specific project requirements makes it a versatile component in diverse construction applications. Adjustments can be made to particle size, chemical composition, and performance characteristics, ensuring optimal results.

4. Cost-Effectiveness Although the initial cost of silica fume may be higher than conventional additives, its effectiveness in enhancing performance can lead to long-term cost savings by reducing maintenance and repair needs.

In conclusion, custom silica fume powder plays a pivotal role in modern construction, combining enhanced performance with sustainability. Its unique properties make it a preferred choice for various applications, fostering durability and longevity in concrete structures. As the industry continues to evolve, the demand for custom silica fume will likely grow, further solidifying its importance in the construction materials landscape.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025