custom sepiolite mineral manufacturer

Custom Sepiolite Mineral Manufacturer Meeting Diverse Industry Needs

In the realm of industrial minerals, sepiolite has garnered significant attention due to its unique properties and versatile applications. As a lightweight, porous clay mineral with fibrous morphology, sepiolite is valued in various sectors, including agriculture, construction, and pharmaceuticals. With the growing demand for high-quality sepiolite, custom sepiolite mineral manufacturers are stepping up to provide tailored solutions that meet the specific requirements of different industries.

Understanding Sepiolite

Sepiolite is a magnesium silicate mineral that is primarily composed of hollow, needle-like particles. This unique structure gives sepiolite remarkable adsorption properties, making it ideal for applications in which moisture retention, odor control, and contaminants absorption are essential. Its natural ability to retain water and nutrients makes it an excellent additive in agricultural formulations, while its fibrous nature lends itself well to applications in construction materials such as cement and plaster.

The Role of Custom Manufacturers

As industries evolve and technologies advance, the need for customized minerals has never been more pronounced. Custom sepiolite mineral manufacturers specialize in tailoring their products to fit specific customer requirements. This includes adjusting particle size, modifying chemical properties, and enhancing overall performance based on the intended application. By providing customized solutions, these manufacturers ensure that industries can optimize their processes and enhance product quality.

For instance, in the agricultural sector, manufacturers might produce sepiolite with specific particle sizes that contribute to the ideal soil texture for various crops. In pharmaceuticals, custom formulations can be developed that enhance the bioavailability of certain compounds. This level of customization not only improves the efficacy of the end products but also fosters innovation within each industry.

custom sepiolite mineral manufacturer

Quality Assurance and Sustainability

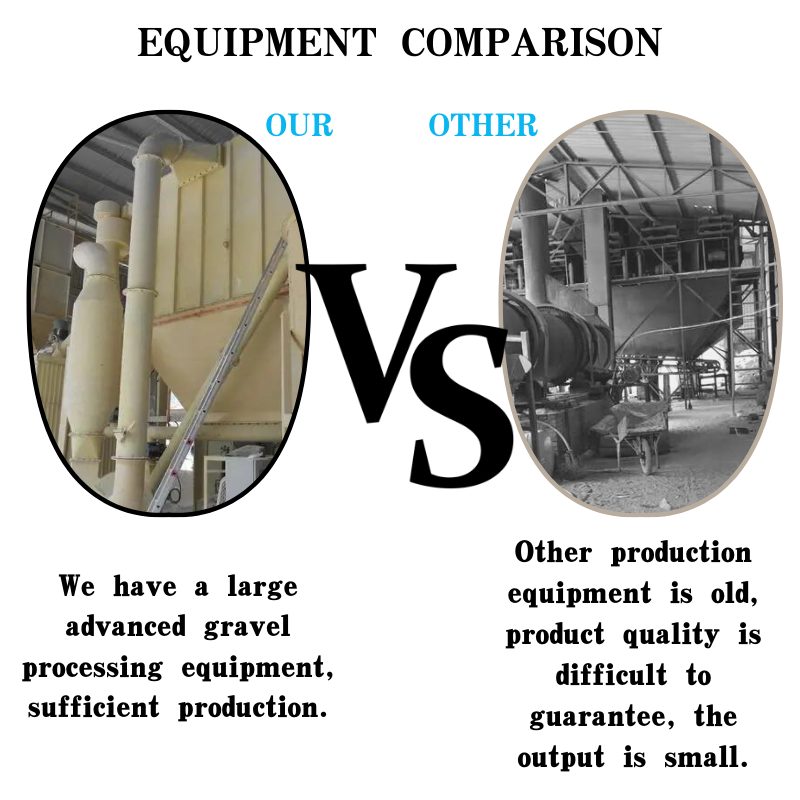

Quality assurance is another critical aspect of the custom sepiolite manufacturing process. Manufacturers are increasingly investing in advanced testing and quality control measures to ensure that their products meet the highest standards. This includes rigorous testing for purity, particle size distribution, and chemical composition. By adhering to strict quality protocols, manufacturers can provide their customers with consistent and reliable products.

Furthermore, many custom sepiolite manufacturers are now focusing on sustainable practices. This includes utilizing environmentally friendly extraction methods, minimizing waste, and ensuring that the sourcing of raw materials adheres to ethical standards. By prioritizing sustainability, these manufacturers not only contribute to environmental conservation but also appeal to a growing market of eco-conscious consumers.

The Future of Sepiolite Manufacturing

As the demand for specialized minerals continues to rise, the future of custom sepiolite mineral manufacturers looks promising. With advancements in technology and materials science, manufacturers will be better equipped to innovate and develop new applications for sepiolite. Potential future uses may include enhanced water retention agents for agriculture, novel absorbents for environmental cleanup, and specialized additives for advanced materials in construction.

In conclusion, custom sepiolite mineral manufacturers play a vital role in bridging the gap between mineral production and industry-specific needs. By providing tailored solutions, ensuring high-quality standards, and embracing sustainable practices, these manufacturers are helping to propel various sectors forward. As industries continue to evolve, the significance of custom sepiolite products will undoubtedly grow, highlighting the importance of innovation and adaptability in the mineral manufacturing landscape.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025