custom perlite in concrete factory

Custom Perlite in Concrete Factories Enhancing Lightweight Concrete Solutions

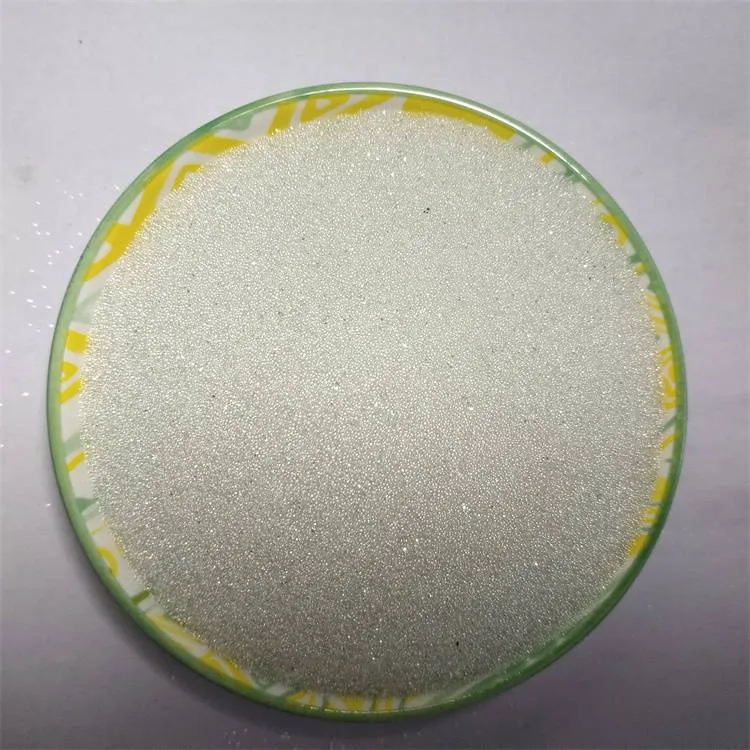

In the world of construction and material science, the integration of innovative materials has significantly revolutionized the way concrete is formulated and utilized. One such remarkable material is perlite, a volcanic glass that undergoes a unique expansion process, resulting in lightweight and highly effective aggregates. The custom application of perlite in concrete factories has enabled the development of specialized lightweight concrete solutions that cater to a myriad of construction needs.

Perlite is known for its excellent insulation properties, low density, and high resistance to fire. When introduced into concrete mixtures, it can drastically reduce the overall weight of the final product without compromising its structural integrity. This characteristic is particularly advantageous in scenarios where reducing the dead load of structures is crucial, such as in multi-story buildings or in renovating existing structures where weight restrictions are a concern.

Customizing perlite for specific applications in concrete factories involves a detailed understanding of the desired characteristics of the final concrete product. By adjusting the quantity and particle size of perlite used in the mix, manufacturers can achieve varying levels of strength and insulation properties. For instance, fine perlite may enhance the insulation capabilities of concrete, making it suitable for residential buildings that require energy efficiency, while coarser perlite may be utilized for structural applications that demand additional strength.

custom perlite in concrete factory

Moreover, the use of custom perlite in the concrete manufacturing process is an environmentally friendly approach. As a natural material, perlite contributes to sustainability efforts within the construction sector. By utilizing lighter aggregates, concrete products require less energy in transportation and installation, reducing the overall carbon footprint of construction activities.

Concrete factories can also benefit from custom perlite solutions through enhanced workability. Because perlite is lightweight, concrete mixtures become easier to handle and pour. This efficiency leads to increased productivity on the job site and can positively impact timelines and labor costs. Furthermore, the adaptability of perlite allows manufacturers to create tailored concrete mixes that meet specific building codes and performance criteria.

In the competitive world of construction and concrete production, the ability to customize materials like perlite presents a significant opportunity for innovation. As architects and engineers increasingly seek lightweight and sustainable building solutions, concrete factories that adopt custom perlite will be at the forefront of meeting these demands. By continuing to explore and expand the potential applications of perlite in concrete, the industry can not only improve building practices but also contribute to wider sustainability goals.

In conclusion, custom perlite in concrete factories represents a powerful combination of efficiency, adaptability, and environmental responsibility. As the construction landscape evolves, the innovative use of materials like perlite will undoubtedly play a pivotal role in shaping the future of concrete technology, paving the way for smarter and more sustainable construction practices.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025