custom organic perlite factory

Custom Organic Perlite Factory A Sustainable Solution for Agriculture

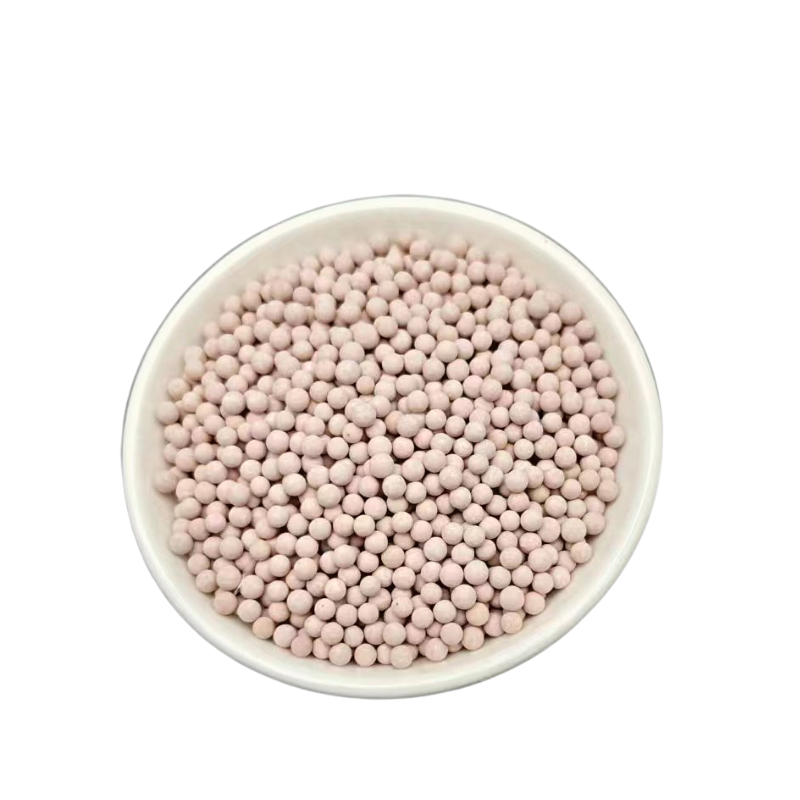

In recent years, the demand for eco-friendly agricultural products has surged, leading to a growing interest in organic inputs that enhance soil health and crop yield. One such product gaining traction is perlite—an inorganic, lightweight volcanic glass that, when heated, expands to form a porous structure. As more farmers and gardeners seek sustainable alternatives, the significance of a custom organic perlite factory becomes increasingly evident.

Perlite is renowned for its remarkable properties. Its aeration qualities improve drainage in soil, allowing oxygen to reach plant roots more effectively. Additionally, perlite helps retain moisture, creating an optimal environment for plants to thrive. These characteristics make it a popular choice among organic farmers who strive to enhance soil structure without resorting to chemical additives.

Establishing a custom organic perlite factory involves several key steps, beginning with sourcing quality raw materials. The foundation of any successful perlite product stems from its volcanic origin. By selecting high-grade perlite ore, manufacturers can ensure that their final product meets stringent organic standards. This adherence to quality is crucial, as it translates directly into the performance and reliability of the perlite used in agricultural applications.

custom organic perlite factory

Another critical aspect of the custom perlite production process is the state-of-the-art expansion technology used during manufacturing. The perlite ore is subjected to high temperatures, causing it to expand and transform into lightweight, white granules. This expansion process not only increases the volume of the material but also enhances its properties, making it even more beneficial for organic farming practices. A custom factory can tailor this process to produce perlite with specific expansion levels and particle sizes suited to various horticultural needs.

Furthermore, a custom organic perlite factory can offer a range of formulations that meet specific customer requirements. Whether for hydroponics, potting mixes, or general gardening, the ability to produce customized blends allows farmers and retailers to cater directly to their target markets. This flexibility not only improves customer satisfaction but also fosters innovation in organic farming practices.

Sustainability is at the heart of the custom organic perlite factory model. By prioritizing environmentally friendly practices, such as energy-efficient processing and sustainable sourcing, these factories can significantly reduce their carbon footprint. Manufacturers can implement recycling programs for packaging materials and invest in renewable energy sources to power their operations. These measures align with the growing consumer preference for sustainable products, allowing businesses to thrive while contributing positively to the environment.

In conclusion, the establishment of a custom organic perlite factory represents a progressive step toward more sustainable agriculture. By providing high-quality, tailored perlite solutions, manufacturers can support organic farmers in their quest for healthier soil and improved crop productivity. As the agricultural landscape continues to evolve, such innovative factories will play a vital role in promoting eco-friendly practices and ensuring a greener future for farming. With the integration of advanced technology and a commitment to sustainability, the custom organic perlite factory stands poised to meet the challenges of the modern agricultural world.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025