custom limestone powder factory

The Rise of Custom Limestone Powder Factories

In recent years, the demand for customized industrial materials has surged across various sectors, especially in construction, agriculture, and manufacturing. One significant player in this emerging trend is the custom limestone powder factory. This facility specializes in producing tailored limestone powder to meet the specific needs of its customers, offering a wide array of applications and benefits.

Limestone, primarily composed of calcium carbonate, is a widely utilized mineral. Its versatility makes it an essential component in various industries. Custom limestone powder factories have identified the need for specialized products that cater to different technical specifications, particle sizes, and purity levels. This custom approach not only enhances the performance of the final product but also promotes sustainability by reducing waste and optimizing resource utilization.

One of the primary applications of custom limestone powder is in the construction industry. Limestone powder is used as a filler in cement and concrete products. By customizing the particle size and morphology of the powder, manufacturers can achieve improved workability and strength in their concrete mixtures. This results in structures that are not only durable but also more cost-effective. The use of high-quality limestone powder can significantly reduce the amount of cement required in construction, thereby lowering carbon emissions associated with cement production.

In agriculture, custom limestone powder plays a critical role in soil amendment and enhancement. Farmers can benefit from finely milled limestone, which helps in neutralizing acidic soils, improving nutrient availability, and promoting healthier plant growth. Customization allows agricultural producers to choose a specific grade of limestone powder that is most suitable for their soil types and farming practices. This targeted approach to soil health contributes to increased crop yields and sustainable farming practices.

custom limestone powder factory

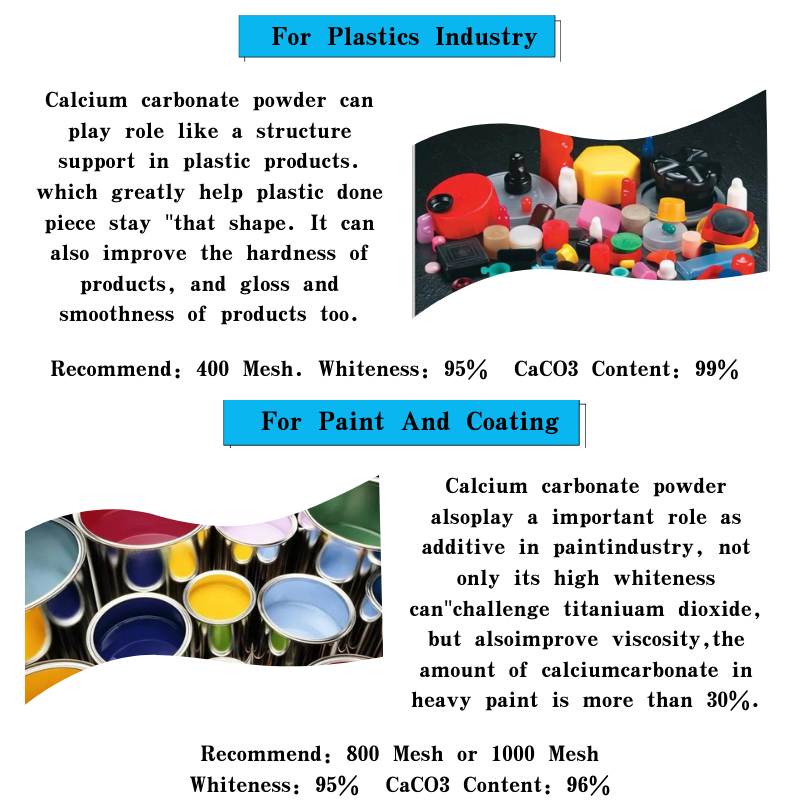

Moreover, the manufacturing sector leverages custom limestone powder in various ways. It can be used in the production of plastics, rubber, and paints, where it serves as a filler that improves the mechanical properties and reduces production costs. By offering tailor-made limestone powder, factories can cater to the specific needs of manufacturers, ensuring their products meet the required standards and performance criteria.

The production process in a custom limestone powder factory is meticulous and often involves several stages, including careful quarrying, strict quality control, and advanced milling techniques. These factories employ state-of-the-art technology to ensure that the finished product meets precise specifications. This commitment to quality has positioned custom limestone powder as a preferred choice for industries looking to enhance their products.

Furthermore, the environmental aspect of using limestone powder cannot be overlooked. As more industries strive to adopt sustainable practices, the mining and processing of limestone into fine powder present a lower environmental impact compared to other alternatives. Custom limestone suppliers are making efforts to utilize energy-efficient processes and promote the use of by-products, thus contributing to a circular economy.

In conclusion, custom limestone powder factories are at the forefront of providing tailored solutions to meet the diverse needs of various industries. By focusing on customization, these facilities enhance product performance, promote sustainability, and address specific client requirements. As the global demand for customized industrial materials continues to grow, the significance of custom limestone powder factories will only increase, paving the way for innovative applications and sustainable practices across multiple sectors.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025