custom diatomite stone factory

Exploring the World of Custom Diatomite Stone Manufacturing

Diatomite stone, a natural material derived from the fossilized remains of diatoms, has become increasingly popular in various industries due to its unique properties and versatility. As environmental concerns grow and the demand for sustainable materials rises, many manufacturers are turning to diatomite for its numerous benefits. This article delves into the fascinating world of custom diatomite stone fabrication, highlighting its applications, advantages, and the processes involved in creating high-quality products from this remarkable material.

Understanding Diatomite A Natural Marvel

Diatomite, also known as diatomaceous earth, is composed primarily of silica and is renowned for its porous structure and lightweight nature. These characteristics make it an ideal material for a range of applications, including filtration, insulation, and even agriculture. The diatomite stone is not only functional but also aesthetically pleasing, often used in decorative items, furniture, and building materials.

Custom Manufacturing Tailoring Solutions to Specific Needs

One of the most appealing aspects of diatomite stone is the ability to customize products to meet specific requirements. Manufacturers often work closely with clients to design and produce diatomite items that suit individual preferences, sizes, and functions. Customization can include variations in texture, color, shape, and size, allowing businesses to create unique offerings that stand out in the market.

Key Applications of Diatomite Stone

The applications of custom diatomite stone are vast and varied. In the construction industry, it is valued for its insulating properties, helping to regulate temperature and improve energy efficiency in buildings. Additionally, diatomite is used in the production of lightweight concrete and as a filler material, contributing to eco-friendly construction practices.

custom diatomite stone factory

In the realm of horticulture, diatomite serves as an excellent soil amendment. Its ability to retain moisture while improving aeration makes it a popular choice among gardeners and agriculturalists. It helps promote healthy root development and is beneficial for various plants, making it a staple in organic farming.

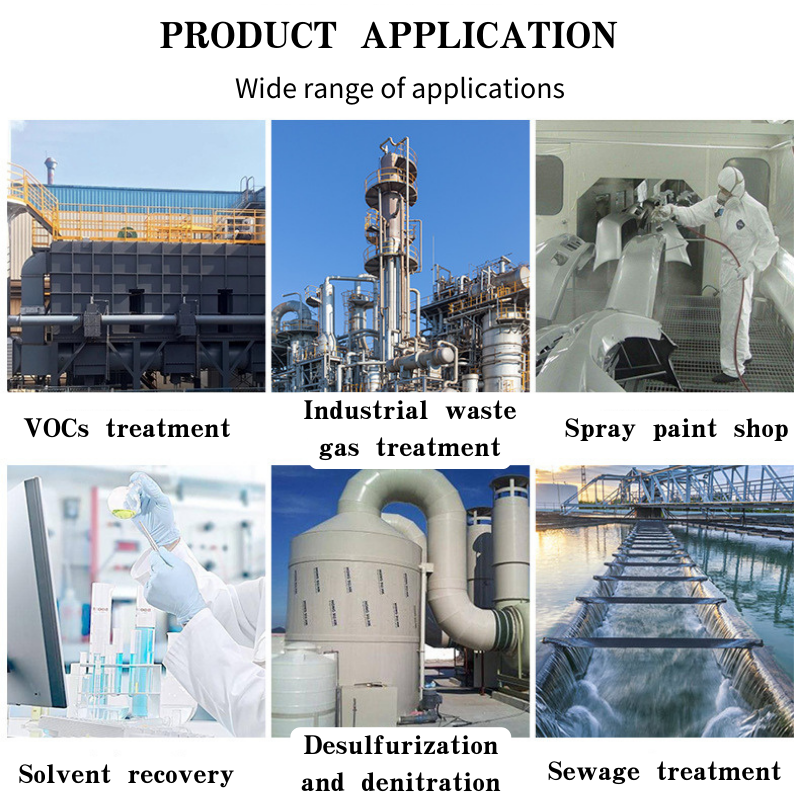

Furthermore, diatomite’s filtration properties are harnessed in industries such as food and beverage, pharmaceuticals, and water treatment. Its porous nature allows it to effectively trap particulates and contaminants, ensuring high-quality products in these critical sectors.

The Manufacturing Process From Raw Material to Finished Product

The journey from raw diatomite to finished custom products involves several steps. Initially, diatomite is mined and processed to remove impurities. The material is then ground into a fine powder, which can be molded, cast, or compressed into various shapes. Modern technological advancements allow for precise manufacturing techniques that ensure consistency and quality in every batch.

Once the desired shape is achieved, the diatomite stone undergoes drying and curing processes. These steps may vary depending on the specific application and desired properties of the final product. Quality control is paramount throughout the manufacturing process, ensuring that each item meets stringent standards before reaching the market.

Conclusion A Bright Future for Custom Diatomite Stone

The custom diatomite stone industry is poised for growth as more businesses recognize the benefits of this versatile material. With an increasing emphasis on sustainability and innovation, diatomite offers an eco-friendly alternative to traditional materials. As manufacturers continue to explore new applications and refine their processes, the market for custom diatomite products is likely to expand, paving the way for a greener and more efficient future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025