1 月 . 22, 2025 01:39

Back to list

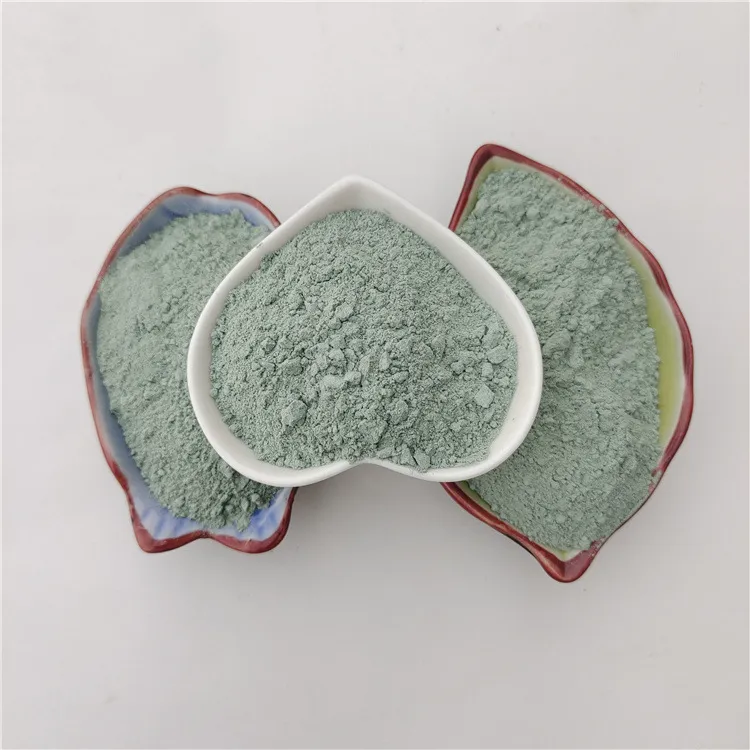

composite mica

Composite mica, a remarkable adaptation of the natural mineral mica, has revolutionized various industries with its exceptional characteristics. Known for its unique composition and impressive versatility, composite mica has steadily gained a strong foothold in markets where durability, thermal stability, and electrical insulation are paramount.

From a commercial standpoint, composite mica is favored not only for its functional advantages but also for its cost-effectiveness. Companies transitioning to composite mica report a decrease in maintenance costs and a longer lifespan of their equipment, which contributes to higher financial savings over time. The material's resistance to environmental degradation further ensures that products made with composite mica remain robust and reliable, even under harsh conditions. Research and development within the field of composite mica continue to push the boundaries of its application. Scientists and materials engineers are actively exploring ways to customize composite mica for niche applications, hence expanding its utility across multiple sectors. Innovations such as flexible composite mica sheets are paving the way for its use in flexible electronics and wearable technology, indicating its potential to disrupt conventional markets and lead the forefront of technological advancement. With its rising prevalence, composite mica also underscores the importance of sustainable material sourcing. Leading producers adhere to strict environmental and safety regulations, ensuring that the production process of composite mica is as eco-friendly as possible. This commitment to sustainability not only enhances the credibility of these producers but also aligns with the growing demand for environmentally responsible industrial practices. In conclusion, composite mica's exceptional thermal resistance, electrical insulating properties, and mechanical durability make it an indispensable material across various industrial applications. Its integration into specialized products continues to showcase its unmatched benefits, positioning it as a material of choice for future innovations. As industries evolve, the demand for high-performance materials like composite mica is expected to surge, heralding a new era of efficiency and reliability in material science. Whether in the arena of high-power electrical applications or the cutting-edge world of flexible electronics, composite mica stands as a testament to the incredible potential of engineered materials.

From a commercial standpoint, composite mica is favored not only for its functional advantages but also for its cost-effectiveness. Companies transitioning to composite mica report a decrease in maintenance costs and a longer lifespan of their equipment, which contributes to higher financial savings over time. The material's resistance to environmental degradation further ensures that products made with composite mica remain robust and reliable, even under harsh conditions. Research and development within the field of composite mica continue to push the boundaries of its application. Scientists and materials engineers are actively exploring ways to customize composite mica for niche applications, hence expanding its utility across multiple sectors. Innovations such as flexible composite mica sheets are paving the way for its use in flexible electronics and wearable technology, indicating its potential to disrupt conventional markets and lead the forefront of technological advancement. With its rising prevalence, composite mica also underscores the importance of sustainable material sourcing. Leading producers adhere to strict environmental and safety regulations, ensuring that the production process of composite mica is as eco-friendly as possible. This commitment to sustainability not only enhances the credibility of these producers but also aligns with the growing demand for environmentally responsible industrial practices. In conclusion, composite mica's exceptional thermal resistance, electrical insulating properties, and mechanical durability make it an indispensable material across various industrial applications. Its integration into specialized products continues to showcase its unmatched benefits, positioning it as a material of choice for future innovations. As industries evolve, the demand for high-performance materials like composite mica is expected to surge, heralding a new era of efficiency and reliability in material science. Whether in the arena of high-power electrical applications or the cutting-edge world of flexible electronics, composite mica stands as a testament to the incredible potential of engineered materials.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025