china volcanic stone factory

China's Volcanic Stone Factories An Overview of Innovation and Tradition

In recent years, the demand for volcanic stone has surged across various industries, from construction to landscaping and interior design. Characterized by its unique aesthetic and durable properties, volcanic stone, also known as pumice or basalt, has become a preferred choice for architects and designers worldwide. As a significant player on the global stage, China has developed an extensive network of volcanic stone factories, reflecting a blend of traditional craftsmanship and modern technology.

Volcanic stone is formed from the rapid cooling of lava, resulting in a porous and lightweight material with impressive strength. This natural stone is often used in various capacities, such as tiles, countertops, and decorative pieces. The properties of volcanic stone make it highly sought after for both indoor and outdoor applications, where its durability and unique textures can enhance visual appeal.

China's Volcanic Stone Factories An Overview of Innovation and Tradition

The production process begins with the careful extraction of volcanic rock from quarries. Workers meticulously select the best material to ensure that only the highest quality stone enters the manufacturing process. Once extracted, the stone undergoes a series of treatments to enhance its aesthetic appeal and functional properties, including cutting, polishing, and fining. Advanced technologies, such as CNC machines and water jet cutting systems, are employed to create precise shapes and designs that meet the increasing demands of contemporary architecture and design.

china volcanic stone factory

One of the standout features of Chinese volcanic stone is its versatility. Factories offer a wide range of finishes, patterns, and colors, catering to various consumer preferences. Whether customers seek a rustic, natural look or a sleek, modern finish, Chinese manufacturers can provide tailored solutions. This adaptability has enabled Chinese volcanic stone to find its way into numerous high-profile projects domestically and internationally, including luxury hotels, residential buildings, and public spaces.

Moreover, sustainability has become a key focus for Chinese volcanic stone factories. As environmental concerns grow, many manufacturers are adopting eco-friendly practices. This includes responsible sourcing of raw materials, minimizing waste during production, and using non-toxic finishes. Additionally, volcanic stone itself is a sustainable option, as it is a natural product with a low carbon footprint compared to artificial alternatives.

Exporting these products has also played a crucial role in the growth of the volcanic stone industry in China. With an increasing number of international clients seeking exotic materials, Chinese factories have expanded their reach beyond borders. Through participation in global trade shows and partnerships with foreign distributors, these manufacturers are successfully promoting their products to a broader audience, solidifying China’s position as a leading exporter of volcanic stone.

In conclusion, China's volcanic stone factories embody a remarkable confluence of tradition and modernity. The unique properties of volcanic stone, coupled with innovative production techniques, have made it a prized material in various sectors. As these factories continue to adapt to market trends and uphold sustainable practices, they are poised to thrive in the competitive landscape of the global stone industry. With a commitment to quality and a respect for both heritage and innovation, China's volcanic stone factories look toward a bright future, contributing significantly to the world of design and architecture.

Share

-

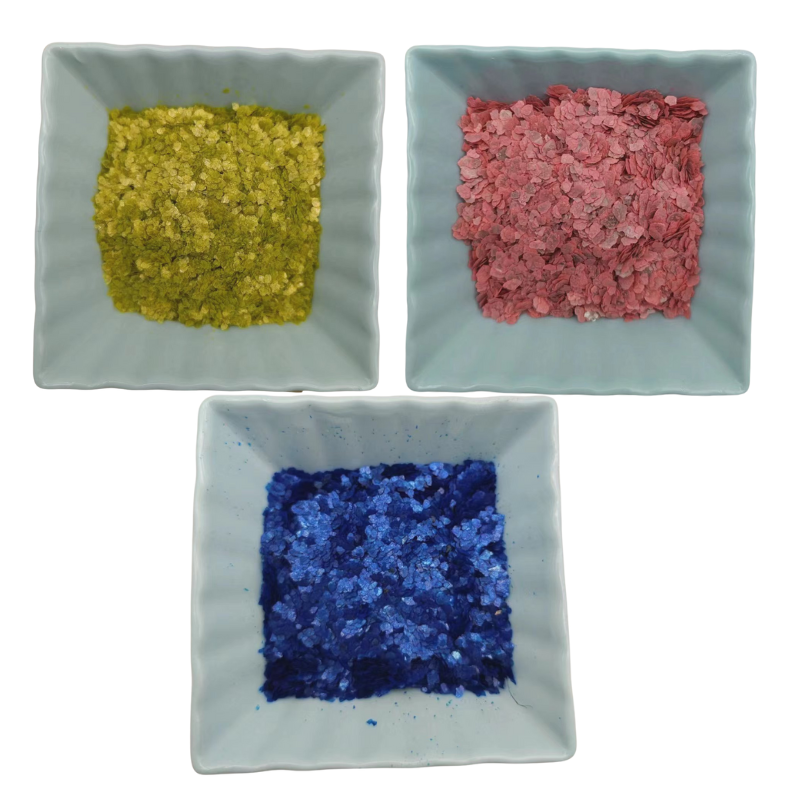

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025