china sodium or calcium bentonite clay factories

The Role of Sodium and Calcium Bentonite Clay Factories in China

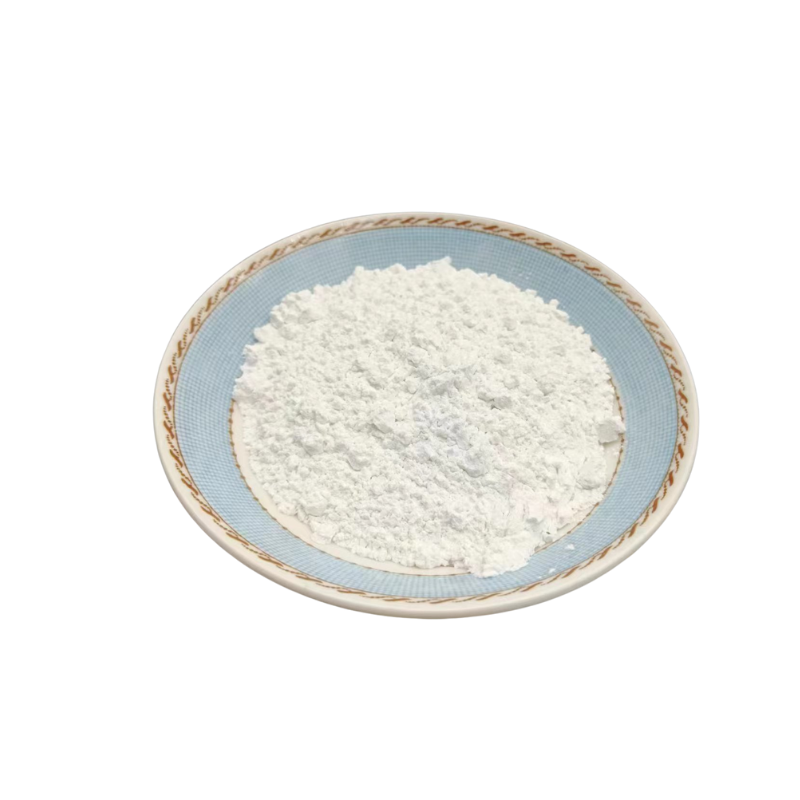

In recent years, China has emerged as a powerhouse in the production of bentonite clay, a versatile mineral used in numerous industries. Among the various types of bentonite, sodium and calcium bentonite are particularly significant due to their unique properties and diverse applications.

Sodium bentonite, known for its high swelling capacity, is widely used in applications such as drilling muds, where it acts as a lubricant and stabilizer in oil and gas extraction. Its ability to form a gel-like substance when mixed with water makes it an ideal agent for sealing and preventing fluid loss during drilling operations. Additionally, sodium bentonite is utilized in the production of cat litter, as it absorbs moisture effectively and controls odors, making it a popular choice among pet owners.

On the other hand, calcium bentonite is characterized by its lower swelling properties and is primarily used in foundry sands, as a binder in iron ore pelletizing, and in various construction and civil engineering applications

. Its effectiveness in clarifying liquids makes it an important component in the food and beverage industries, aiding in the purification of edible oils and juices.china sodium or calcium bentonite clay factories

China's bentonite clay factories have capitalized on the country's abundant natural resources, leveraging advanced mining technologies to extract high-quality clay. The production process typically involves crushing and milling the raw bentonite to achieve the desired particle size and purity. These factories adhere to stringent quality control measures to ensure that their products meet international standards, making Chinese bentonite competitive in the global market.

Moreover, with the increasing demand for eco-friendly and sustainable materials, the bentonite industry in China is evolving. Factories are investing in green technologies and sustainable practices to minimize their environmental impact. This includes recycling water used in production processes and implementing waste management systems that reduce the carbon footprint.

The export of sodium and calcium bentonite from China has also gained momentum, fulfilling the needs of international markets in North America, Europe, and Asia. The versatility of bentonite clay, combined with China's robust manufacturing capabilities, positions the country as a key player in the global mineral market.

In conclusion, sodium and calcium bentonite clay factories in China not only contribute significantly to the domestic economy but also play a crucial role in various global industries. As innovation and sustainability continue to shape the landscape of mineral production, China's bentonite industry is poised for further growth and development, meeting the ever-evolving needs of consumers and industries worldwide.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025