China's Leading Manufacturer of White Zeolite for Diverse Industrial Applications and Solutions

China White Zeolite Factory A Hub of Innovation and Sustainability

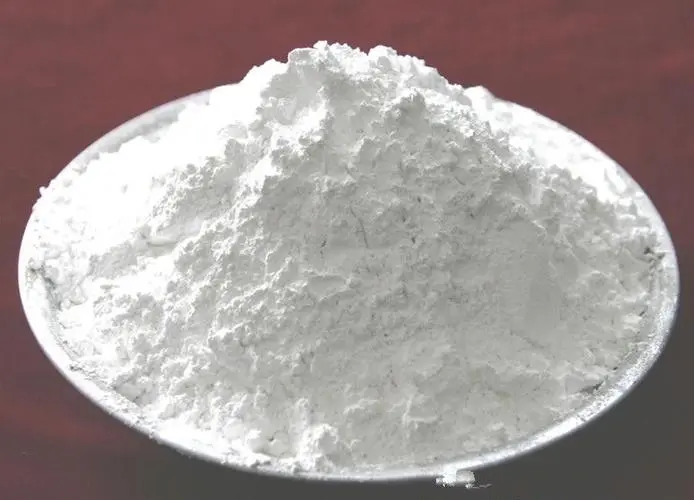

Zeolites are naturally occurring or synthetically produced minerals known for their unique porous structures and ion-exchange properties. Among the various types available, white zeolite has gained particular attention due to its versatile applications in industries such as agriculture, water treatment, and environmental remediation. China, a global leader in zeolite production, has established numerous factories specializing in white zeolite, focusing on innovation and sustainability to meet the growing market demand.

China White Zeolite Factory A Hub of Innovation and Sustainability

In addition to agricultural applications, white zeolite plays a critical role in water treatment. The porous structure of zeolite allows it to act as a natural filter, trapping contaminants and unwanted pollutants. With China facing significant water pollution challenges, the production of high-grade white zeolite has become increasingly important. Local factories are responding by enhancing their production capabilities, ensuring that they can provide zeolite that meets stringent environmental regulations. Moreover, the use of zeolite in water treatment processes helps reduce the reliance on chemical purifiers, thereby minimizing environmental impact.

china white zeolite factory

Environmental remediation is another area where Chinese white zeolite factories are making significant contributions. The ability of zeolite to adsorb heavy metals and other toxins from contaminated soil and water has positioned it as a key player in restoring polluted environments. Factories in China are not only producing zeolite but also engaging in innovative projects aimed at polluted areas, demonstrating a commitment to ecological restoration. Collaborations between industries and government entities are fostering a holistic approach to environmental challenges, with white zeolite being a central component of these initiatives.

Sustainability is a primary focus for Chinese zeolite factories. The country has implemented stricter environmental regulations in response to growing global awareness of sustainability issues. As a result, zeolite manufacturers are adopting eco-friendly production methods and sourcing raw materials responsibly. Many factories now aim for zero waste in their operations, recycling by-products and utilizing renewable energy sources where possible. This commitment not only reduces their carbon footprint but also sets a benchmark for other industries to follow.

The future of white zeolite production in China looks promising. As the global demand for environmentally friendly products continues to rise, the role of zeolites in various sectors is expected to expand. Factories are likely to explore new applications, such as in construction materials and detergents, further enhancing the mineral's value. Additionally, ongoing advancements in production techniques will ensure that China remains a dominant player in the international zeolite market.

In conclusion, the white zeolite factories in China are at the forefront of innovation and sustainability. Their contributions to agriculture, water treatment, and environmental remediation reflect a broader commitment to addressing global challenges. With ongoing investments in research and a firm focus on sustainable practices, these factories are not just producing a commodity; they are actively participating in the creation of a greener and more sustainable future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025