3 月 . 07, 2025 05:34

Back to list

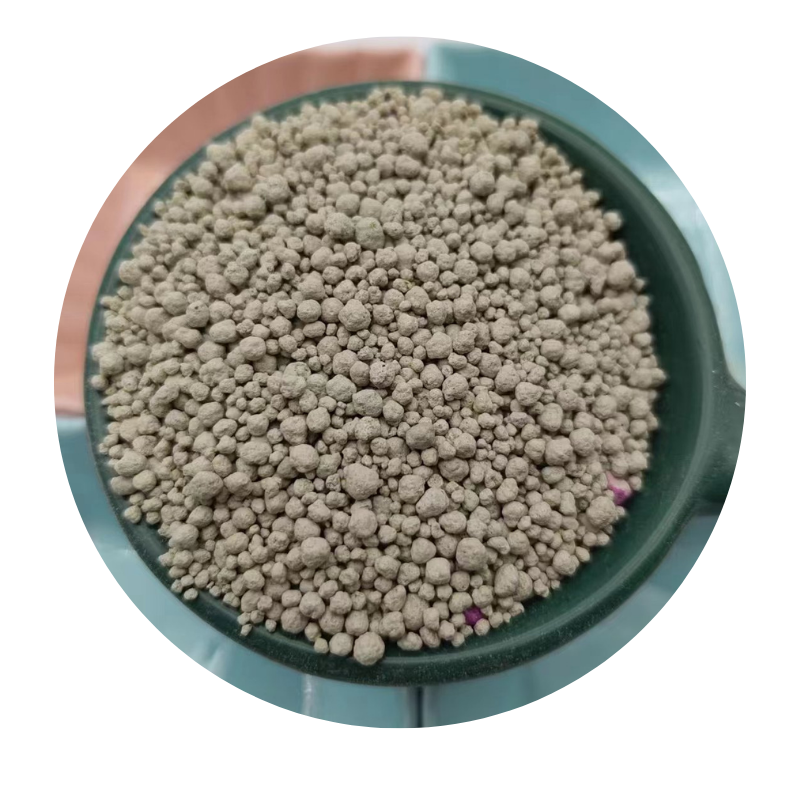

A large number of wholesale high quality perlite planting coatings industry special

China's economic boom has paved the way for a plethora of advancements in various industries, and the construction sector is no exception. Among the innovative materials gaining traction is perlite—a versatile volcanic glass used extensively in concrete mixtures. This article delves into the multifaceted roles of perlite in concrete, particularly focusing on its application and benefits when integrated into construction projects.

The environmental benefits of using perlite in concrete should not be understated. The lightweight nature of perlite reduces the overall need for raw materials, such as cement, which is known for its significant carbon footprint during production. Hence, incorporating perlite can be viewed as a step towards more sustainable construction practices, aligning with global trends of reducing carbon emissions and promoting eco-friendly building materials. China, being one of the leading producers of perlite, has mastered the efficient extraction, processing, and distribution of this material, ensuring its availability in construction projects across the country. This domestic production supports the local economy and diminishes the reliance on imports, offering more cost-effective solutions for the domestic market. However, success in the application of perlite in concrete hinges on proper formulation. Expertise in the optimal mixing ratios and understanding how it interacts with other components is essential. Several research initiatives and experiments conducted by Chinese universities and construction companies have cemented China’s authority and expertise in utilizing perlite, providing a well of knowledge for construction professionals to draw from. Numerous case studies highlight the effectiveness of perlite in concrete across various environmental conditions in China, from the cold climates in the north to the humid regions in the south. This extensive knowledge base assures builders and developers of the reliability and versatility of perlite-enhanced concrete. In summary, the integration of perlite into concrete presents a compelling case for builders and developers aiming for efficiency, sustainability, and durability in their projects. As China continues to lead in innovation and production, perlite-laden concrete stands poised to redefine the future of construction, emphasizing performance, environmental consciousness, and cost-effectiveness. The precedent set by Chinese advancements in perlite usage undeniably offers a blueprint for global adaptation, reinforcing the nation's position as a leader in construction material innovation.

The environmental benefits of using perlite in concrete should not be understated. The lightweight nature of perlite reduces the overall need for raw materials, such as cement, which is known for its significant carbon footprint during production. Hence, incorporating perlite can be viewed as a step towards more sustainable construction practices, aligning with global trends of reducing carbon emissions and promoting eco-friendly building materials. China, being one of the leading producers of perlite, has mastered the efficient extraction, processing, and distribution of this material, ensuring its availability in construction projects across the country. This domestic production supports the local economy and diminishes the reliance on imports, offering more cost-effective solutions for the domestic market. However, success in the application of perlite in concrete hinges on proper formulation. Expertise in the optimal mixing ratios and understanding how it interacts with other components is essential. Several research initiatives and experiments conducted by Chinese universities and construction companies have cemented China’s authority and expertise in utilizing perlite, providing a well of knowledge for construction professionals to draw from. Numerous case studies highlight the effectiveness of perlite in concrete across various environmental conditions in China, from the cold climates in the north to the humid regions in the south. This extensive knowledge base assures builders and developers of the reliability and versatility of perlite-enhanced concrete. In summary, the integration of perlite into concrete presents a compelling case for builders and developers aiming for efficiency, sustainability, and durability in their projects. As China continues to lead in innovation and production, perlite-laden concrete stands poised to redefine the future of construction, emphasizing performance, environmental consciousness, and cost-effectiveness. The precedent set by Chinese advancements in perlite usage undeniably offers a blueprint for global adaptation, reinforcing the nation's position as a leader in construction material innovation.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025