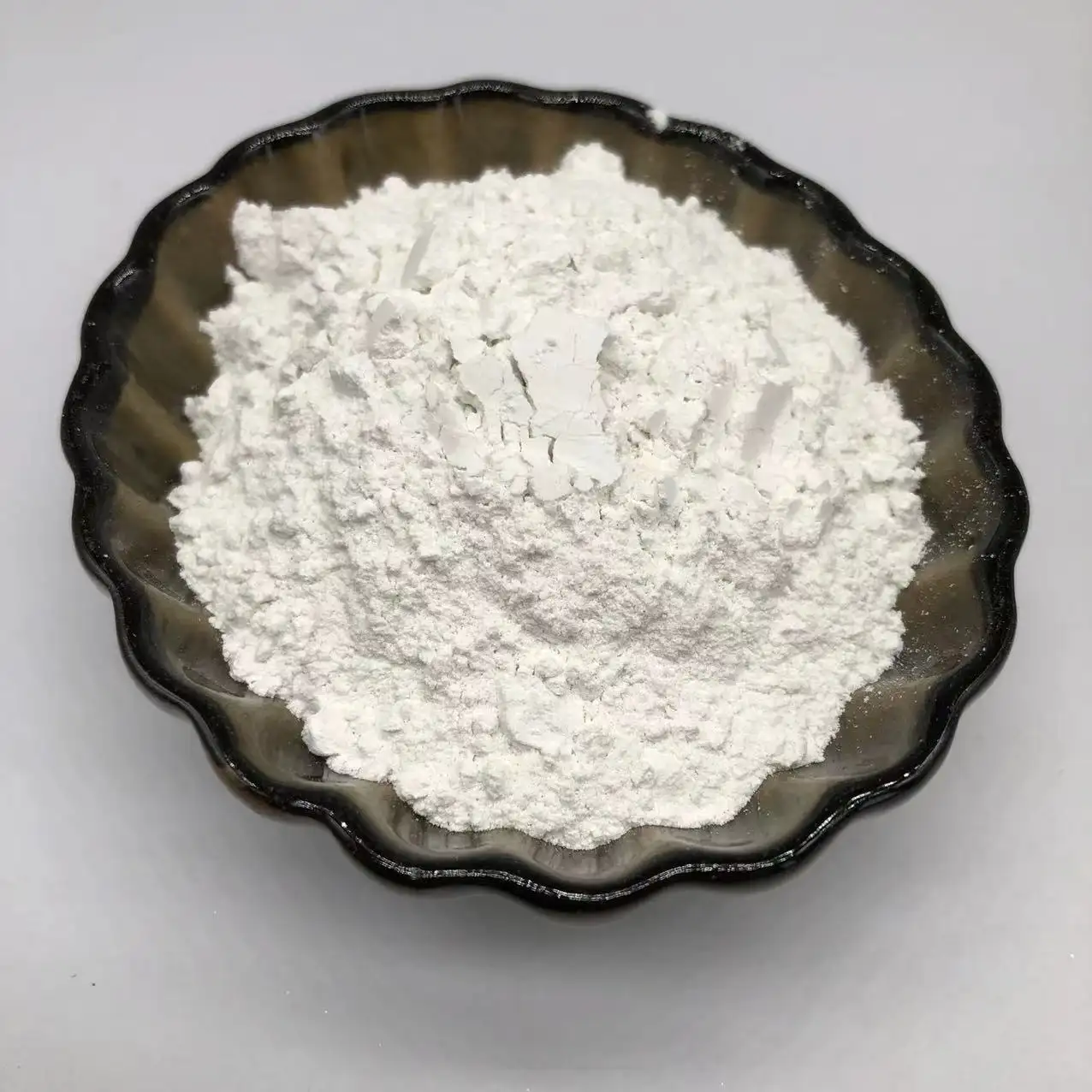

china limestone powder for paint

The Use of Limestone Powder in Paint Production in China

Limestone powder, derived from the milling and processing of limestone rocks, has found significant utility across various industries, one of which is the paint manufacturing sector. In China, where the demand for high-quality paints continues to rise due to rapid urbanization and industrial growth, limestone powder plays an integral role in enhancing paint formulations.

Limestone, primarily composed of calcium carbonate (CaCO3), offers numerous benefits when incorporated into paint. It serves not only as a pigment but also as a filler that improves the physical properties of paint. The Chinese paint industry benefits from the use of high-purity limestone powder for numerous reasons, including its availability, cost-effectiveness, and environmental friendliness.

The Use of Limestone Powder in Paint Production in China

Furthermore, limestone powder is an excellent filler that helps to reduce the overall production costs of paints. By partially replacing more expensive pigments, manufacturers can optimize their formulations without compromising on quality. This cost-effectiveness is particularly crucial in the highly competitive paint market in China, where companies are constantly seeking to increase their profit margins while maintaining product excellence.

china limestone powder for paint

In addition to economic advantages, the use of limestone powder aligns with the increasing environmental regulations in the paint industry. As industries worldwide move towards sustainability, limestone powder provides a relatively eco-friendly alternative to synthetic fillers and pigments. It is a naturally occurring material that reduces the environmental footprint of paint production. Additionally, limestone powder is non-toxic, making it safe for use in residential and commercial applications, thus promoting healthier indoor air quality.

The expansion of the construction and automotive industries in China has significantly increased the demand for both decorative and protective coatings, further driving the use of limestone powder in paints. As these sectors evolve, there is a growing trend towards formulations that include sustainable and natural materials. Companies are increasingly investing in research and development to enhance the performance of limestone powder in paint applications, exploring innovative ways to improve durability, weather resistance, and overall paint lifespan.

Moreover, China's rich deposits of limestone, spanning various regions, ensure a stable and affordable supply of this essential raw material. Local sourcing has substantial logistical benefits, reducing transportation costs and time, which further enhances the competitiveness of Chinese paint manufacturers in the global market.

In conclusion, limestone powder has emerged as a vital ingredient in the paint industry in China, providing a combination of performance, cost-effectiveness, and environmental benefits. As the market continues to evolve, the role of limestone powder is likely to expand, with manufacturers increasingly recognizing its potential as both a functional and sustainable component. The growing focus on environmentally friendly products coupled with high-quality standards will undoubtedly shape the future of paint formulations, making limestone powder an indispensable element in the landscape of China's paint industry. This shift not only reflects the country's industrial ambitions but also aligns with global trends towards sustainability, innovation, and efficiency in manufacturing processes.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025