Large Perlite Manufacturers in China and Their Production Capabilities

Exploring China's Large Perlite Factories A Comprehensive Overview

Perlite, a volcanic glass that expands when heated, is a versatile material with myriad applications, notably in construction, horticulture, and industrial processes. In recent years, China has emerged as a leading producer of perlite, significantly impacting global supply chains. This article delves into the characteristics of large perlite factories in China, their production processes, the significance of perlite, and the environmental considerations associated with this industry.

The Importance of Perlite

Perlite is primarily valued for its lightweight and insulative properties. In horticulture, it is used as a soil amendment to improve aeration and drainage, thereby promoting healthy plant growth. In construction, expanded perlite serves as a lightweight aggregate in concrete, enhancing thermal insulation and fire resistance. Moreover, perlite acts as an effective filtration aid in various industrial applications, including wastewater treatment and food processing. The diverse utilization of perlite underscores its importance, bolstering the demand for large-scale production facilities.

China's Perlite Production Landscape

China's perlite industry has witnessed significant growth over the past few decades, driven by the country's booming construction sector and growing horticultural needs. The abundance of natural perlite deposits across the country has led to the establishment of numerous large perlite factories, particularly in regions like Xinjiang, Qinghai, and Inner Mongolia, where volcanic activity has resulted in extensive perlite reserves.

These factories are often equipped with advanced technology designed for efficient extraction and expansion of perlite. The production process typically involves mining raw perlite ore, followed by crushing and grinding. Once the ore reaches the desired particle size, it is heated in furnaces at high temperatures, causing it to expand into lightweight, granular particles. This expansion can increase the volume of raw perlite by up to 20 times, resulting in a highly versatile end product.

Technological Innovations in Perlite Manufacturing

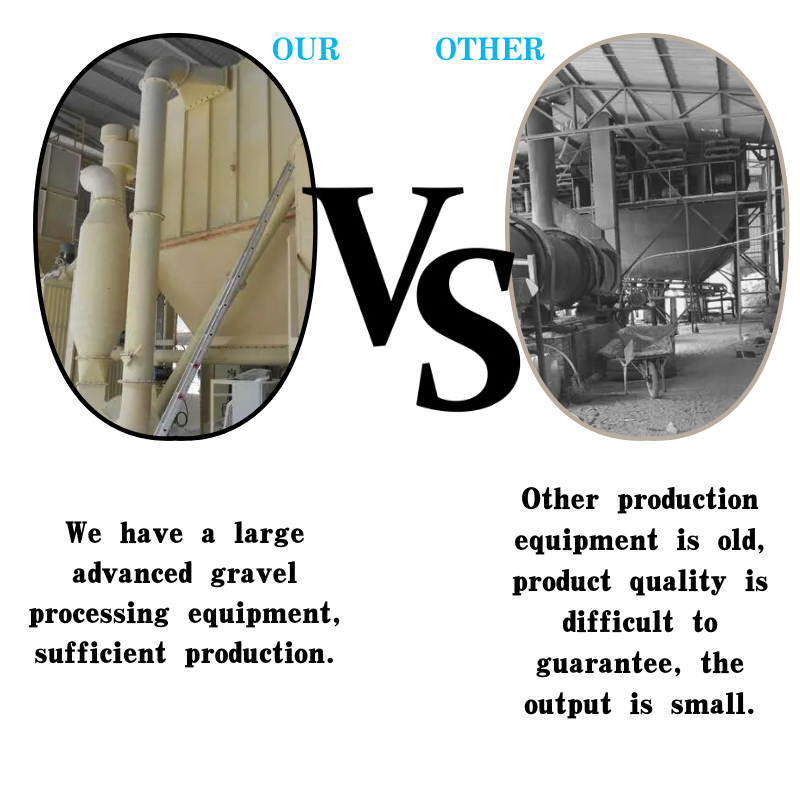

In recent years, many large perlite factories in China have adopted technological innovations to enhance productivity and sustainability. Automation and process optimization have become crucial in increasing output while minimizing waste. Additionally, some factories are integrating green technologies, such as energy-efficient furnaces and dust suppression systems, to reduce their environmental footprint.

china large perlite factories

The use of advanced control systems allows for real-time monitoring of production processes, ensuring consistent quality and reducing energy consumption. Investing in research and development has also enabled factories to explore novel applications for perlite, further expanding its market potential.

Global Market and Export Opportunities

As one of the largest producers of perlite, China plays a pivotal role in the global market. The country's output meets not only domestic demand but also extensive international needs. Major importers of Chinese perlite include countries in North America, Europe, and the Asia-Pacific region, where the demand for construction materials and horticultural products is on the rise.

However, competition in the global perlite market is intensifying, with other countries also ramping up production. As such, large perlite factories in China are striving to maintain a competitive edge by improving product quality and diversifying their offerings. By developing specialized perlite products – such as coarse, fine, and microsized variants – these factories aim to cater to specific market segments and customer needs.

Environmental Considerations

While the growth of large perlite factories in China has economic benefits, it is essential to address the environmental challenges associated with this industry. Mining activities can lead to landscape disruption, habitat loss, and soil degradation if not managed properly. Therefore, many factories are implementing more sustainable practices, such as rehabilitation efforts for mined areas and responsible water management protocols.

Furthermore, as global awareness of environmental issues increases, consumers and regulators are pushing for greater transparency in factory operations. Companies that prioritize sustainability and demonstrate a commitment to minimizing their environmental impact are likely to enjoy a competitive advantage in the market.

Conclusion

China's large perlite factories are at the forefront of a growing industry that plays a crucial role in several sectors. With advancements in technology, a focus on sustainability, and an expanding global market, these factories are well-positioned to continue their dominance in perlite production. As demand for environmentally friendly construction and horticultural materials rises, the importance of perlite and the factories that produce it will only increase, highlighting the need for responsible and innovative practices in this vital industry.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025