2 月 . 14, 2025 22:45

Back to list

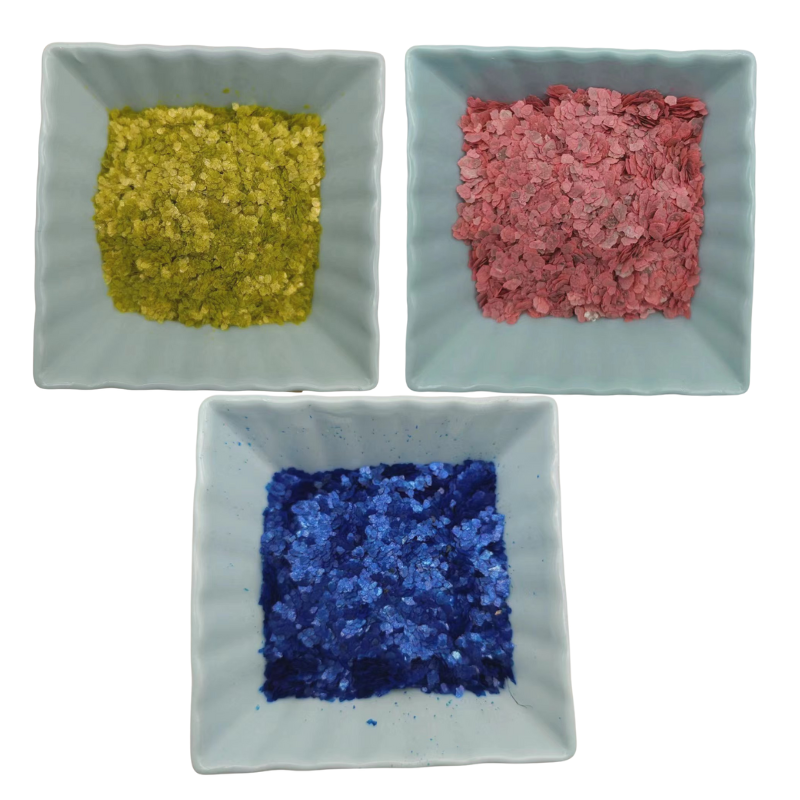

china glass beads road paint

Navigating the dynamic realm of road safety and infrastructure involves a nuanced understanding of materials that enhance visibility and durability. Among such innovations, China glass beads have emerged as a pivotal component in road paint, significantly contributing to safer driving conditions and longer-lasting paint performance.

From an authoritative perspective, numerous studies and field tests validate the effectiveness of glass beads in road safety applications. The Federal Highway Administration (FHWA) and other road safety authorities endorse the use of glass beads for their cost-effectiveness and safety enhancement capabilities. Furthermore, industries involved in road construction benefit from these endorsements as they provide credibility when proposing these solutions in infrastructure projects. Trustworthiness is bolstered by the fact that many international standards and certifications, such as ISO and EN, oversee the quality and environmental compliance of glass beads used in road paints. These standards ensure that the beads are produced sustainably and are safe for the environment, resonating well with current global priorities on sustainable development. Incorporating China glass beads into road paint not only optimizes safety and longevity but also aligns with broader industry trends towards eco-friendly, sustainable solutions. As concerns about road safety and the environmental impact of construction materials grow, the adoption of these beads is likely to expand. They represent a touchstone of modern engineering practices that prioritize innovation, safety, and sustainability. The world of road safety is ever-evolving, with new technologies continually being developed to meet stringent safety standards and environmental considerations. In this context, China glass beads represent more than just a component of road paint; they are emblematic of a forward-thinking approach to infrastructural development that balances safety, cost-efficiency, and sustainability. For stakeholders in the field, including urban planners, construction companies, and government agencies, understanding and utilizing these advantages can lead to significantly improved outcomes for both road users and their operational goals.

From an authoritative perspective, numerous studies and field tests validate the effectiveness of glass beads in road safety applications. The Federal Highway Administration (FHWA) and other road safety authorities endorse the use of glass beads for their cost-effectiveness and safety enhancement capabilities. Furthermore, industries involved in road construction benefit from these endorsements as they provide credibility when proposing these solutions in infrastructure projects. Trustworthiness is bolstered by the fact that many international standards and certifications, such as ISO and EN, oversee the quality and environmental compliance of glass beads used in road paints. These standards ensure that the beads are produced sustainably and are safe for the environment, resonating well with current global priorities on sustainable development. Incorporating China glass beads into road paint not only optimizes safety and longevity but also aligns with broader industry trends towards eco-friendly, sustainable solutions. As concerns about road safety and the environmental impact of construction materials grow, the adoption of these beads is likely to expand. They represent a touchstone of modern engineering practices that prioritize innovation, safety, and sustainability. The world of road safety is ever-evolving, with new technologies continually being developed to meet stringent safety standards and environmental considerations. In this context, China glass beads represent more than just a component of road paint; they are emblematic of a forward-thinking approach to infrastructural development that balances safety, cost-efficiency, and sustainability. For stakeholders in the field, including urban planners, construction companies, and government agencies, understanding and utilizing these advantages can lead to significantly improved outcomes for both road users and their operational goals.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025