China's Leading Factories for High-Quality Concrete Pigments and Their Innovations

Exploring China's Concrete Pigment Industry A Comprehensive Overview

China has emerged as a global leader in various industrial sectors, and the concrete pigment industry is no exception. With the rapid growth of the construction industry driven by urbanization and infrastructure development, the demand for high-quality concrete pigments has surged. This article delves into the intricacies of concrete pigment factories in China, examining their production processes, innovations, challenges, and contributions to the global market.

The Significance of Concrete Pigments

Concrete pigments enhance the aesthetic appeal and durability of concrete. They are used in a myriad of applications, ranging from decorative paving stones to colored concrete for buildings. The primary types of pigments used include organic and inorganic pigments, with China specializing in a wide range of both. The burgeoning construction industry, especially in urban areas, has propelled the demand for these pigments, leading to an increase in production capacity among factories.

Production Processes in Chinese Factories

The production of concrete pigments in China involves several key processes that ensure quality and consistency. Most factories utilize either dry powder or liquid pigment formulations. The dry pigment manufacturing involves mixing raw materials, which are then ground to a fine powder. Quality control is critical at this stage, as particle size can significantly affect the color quality and dispersion in concrete.

On the other hand, the liquid pigments undergo a different preparation method, often incorporating additives to enhance stability and shelf life. Manufacturing facilities emphasize automation and precision in their processes, utilizing advanced machinery to minimize human error and increase efficiency.

Innovations in Concrete Pigment Production

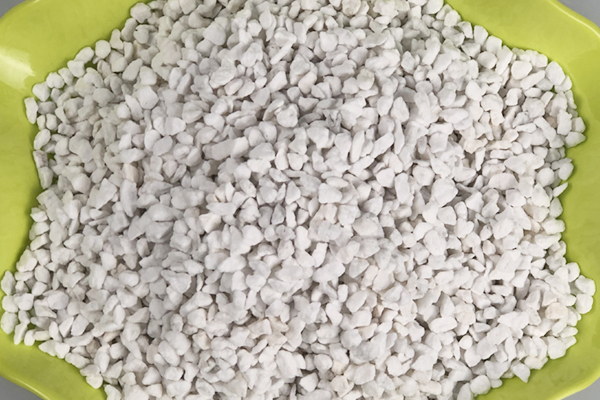

china concrete pigment factories

Chinese concrete pigment factories are not merely content with traditional manufacturing techniques; they are at the forefront of innovation. Research and development efforts are dedicated to creating new formulations that offer improved color stability and UV resistance, ensuring that colored concrete maintains its vibrancy over time. Furthermore, eco-friendly pigments are gaining traction, responding to the increasing global demand for sustainable construction materials. These innovations not only meet domestic needs but also cater to international markets increasingly focused on sustainability.

Challenges Facing the Industry

Despite its growth, the concrete pigment industry in China faces several challenges. One significant issue is the competition from low-cost alternatives that may compromise quality. Many factories are pressured to reduce prices, which can lead to a decrease in the overall quality of pigments supplied to the market.

Additionally, environmental regulations are becoming stricter, requiring factories to adapt their production methods to minimize their ecological footprint. This transition can be costly and complex, particularly for smaller manufacturers who may struggle to invest in clean technologies.

The Global Impact of Chinese Concrete Pigment Factories

China's concrete pigment factories play a crucial role in the global supply chain. With a substantial production capacity, they export pigments to various countries, contributing significantly to the global market. The quality and variety of pigments produced are well-regarded, allowing China to maintain a competitive edge. Countries in need of reliable suppliers for construction materials often turn to Chinese manufacturers.

Conclusion

The concrete pigment industry in China exemplifies the country's manufacturing prowess and its capacity for innovation. As urban development continues to expand, the demand for high-quality pigments will likely remain strong. Navigating the challenges of competition and environmental regulations will be crucial for the industry’s sustainable growth. In doing so, Chinese concrete pigment factories will not only solidify their position in the global market but also contribute to the advancement of more aesthetically pleasing and durable construction practices worldwide. As the industry evolves, it will be exciting to witness how these factories adapt and innovate to meet the challenges of the future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025