2 月 . 18, 2025 12:40

Back to list

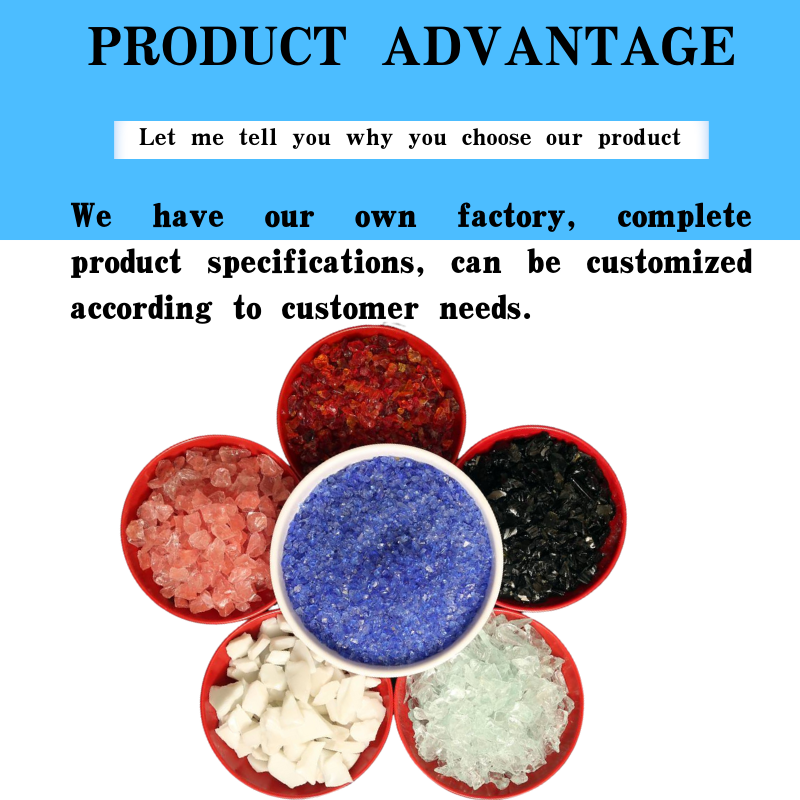

A large number of wholesale high quality perlite planting coatings industry special

China's cement-perlite composite materials have been gaining attention for their unique properties, offering innovative solutions for construction and insulation needs. These materials capitalize on the strengths of both cement and perlite, resulting in composite products that boast superior thermal insulation, lightweight attributes, and enhanced durability. This article delves into the experiences of utilizing these materials, highlighting their expertise-based applications, authoritative quality standards, and establishes a trustworthy outlook for stakeholders contemplating their use.

From an expertise standpoint, Chinese manufacturers have mastered the art of optimizing the ratio of cement to perlite, ensuring the composites achieve the desired balance of strength and insulation. The successful application of these materials in various large-scale projects across China sets a benchmark for quality and performance, showcasing the expertise and innovative thinking prevalent in the industry. Authoritative endorsements of Chinese cement-perlite composites are evident in their compliance with international building standards and certifications. These products often undergo rigorous testing to meet or exceed the criteria set by global construction safety and performance standards. Such endorsements not only bolster their reputation in international markets but also assure potential buyers of their reliability and durability. Trustworthiness in the use of cement-perlite composites is reflected in the long-term performance outcomes observed in completed projects. Buildings constructed with these materials often report higher durability, reduced maintenance needs, and consistent thermal performance over the years. Moreover, Chinese manufacturers are known for their commitment to quality, employing comprehensive quality control measures throughout the production process. In conclusion, China's cement-perlite products represent a blend of experience, expertise, authority, and trustworthiness. Their application in global construction projects positions them as a valuable asset in contemporary building practices. The unique combination of reduced weight, enhanced thermal performance, and structural integrity makes these composites a preferred choice for innovative and sustainable building solutions. As the global construction industry seeks to balance cost, efficiency, and environmental concerns, cement-perlite composites from China are poised to play an increasingly pivotal role.

From an expertise standpoint, Chinese manufacturers have mastered the art of optimizing the ratio of cement to perlite, ensuring the composites achieve the desired balance of strength and insulation. The successful application of these materials in various large-scale projects across China sets a benchmark for quality and performance, showcasing the expertise and innovative thinking prevalent in the industry. Authoritative endorsements of Chinese cement-perlite composites are evident in their compliance with international building standards and certifications. These products often undergo rigorous testing to meet or exceed the criteria set by global construction safety and performance standards. Such endorsements not only bolster their reputation in international markets but also assure potential buyers of their reliability and durability. Trustworthiness in the use of cement-perlite composites is reflected in the long-term performance outcomes observed in completed projects. Buildings constructed with these materials often report higher durability, reduced maintenance needs, and consistent thermal performance over the years. Moreover, Chinese manufacturers are known for their commitment to quality, employing comprehensive quality control measures throughout the production process. In conclusion, China's cement-perlite products represent a blend of experience, expertise, authority, and trustworthiness. Their application in global construction projects positions them as a valuable asset in contemporary building practices. The unique combination of reduced weight, enhanced thermal performance, and structural integrity makes these composites a preferred choice for innovative and sustainable building solutions. As the global construction industry seeks to balance cost, efficiency, and environmental concerns, cement-perlite composites from China are poised to play an increasingly pivotal role.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025