China's Use of Fly Ash in Concrete Enhances Manufacturing Efficiency and Sustainability

The Role of Fly Ash in Concrete Manufacturing in China

In recent years, China has emerged as a leading player in the global construction industry, where innovation and sustainability are becoming increasingly important. One of the notable developments in this field is the incorporation of fly ash into concrete manufacturing. Fly ash, a byproduct of coal combustion in power plants, has garnered attention for its potential to enhance the properties of concrete while also addressing environmental concerns.

Advantages of Using Fly Ash in Concrete

1. Improved Durability Fly ash can significantly increase the durability of concrete. When used as a partial replacement for Portland cement, it improves the concrete's resistance to chemical attacks, reduces permeability, and increases strength over time. This is particularly crucial in areas prone to harsh weather conditions or exposure to aggressive chemicals.

2. Workability and Finish The inclusion of fly ash enhances the workability of concrete. It allows for a smoother mix, reducing the effort required for placement and finishing. This improved workability is particularly beneficial in large-scale construction projects where efficiency is key.

3. Reduction of Carbon Footprint By replacing a portion of Portland cement with fly ash, manufacturers can decrease the overall carbon emissions associated with concrete production. This not only helps in mitigating the environmental impact of construction but also aligns with global efforts to fight climate change. Given that cement production is one of the largest sources of CO2 emissions, the use of fly ash represents a significant step towards sustainable construction practices.

4. Cost Efficiency Fly ash is often less expensive than Portland cement. Using it as a partial replacement can lead to cost savings for manufacturers and construction companies. Furthermore, as fly ash is a byproduct, its utilization helps in reducing waste and promotes a circular economy.

Challenges and Considerations

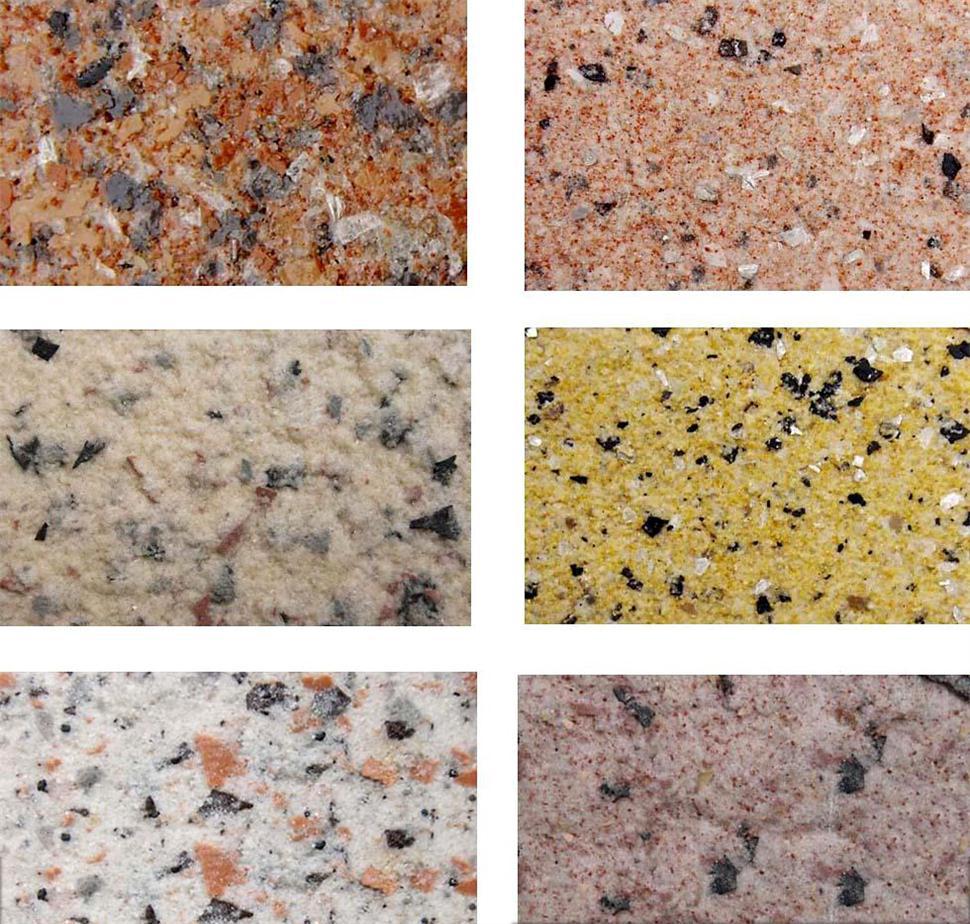

china adding fly ash to concrete manufacturer

While the benefits of using fly ash in concrete are clear, there are challenges that manufacturers must navigate. The quality of fly ash can vary significantly depending on its source, which can affect the performance of the final concrete product. It is essential for manufacturers to ensure that the fly ash they use meets the necessary specifications and standards for construction.

Additionally, there is a growing concern regarding the environmental impact of coal-fired power plants from which fly ash is derived. Efforts must be made to promote cleaner energy sources and better coal combustion technologies to minimize the negative effects associated with fly ash production.

The Future of Fly Ash in Concrete

As China continues to invest in infrastructure development, the reliance on sustainable materials like fly ash is expected to grow. Innovations in concrete technology, including the ongoing research into alternative binding materials and advanced concrete compositions, will further enhance the role of fly ash in the industry.

Government policies aimed at promoting sustainable practices and reducing carbon emissions in construction will also play a critical part in shaping the future of fly ash usage. By creating favorable conditions for the adoption of eco-friendly materials, China can lead by example in the global construction sector.

Conclusion

In conclusion, the addition of fly ash to concrete manufacturing represents a significant advancement in the construction industry in China. By leveraging the benefits of this pozzolanic material, manufacturers can produce high-quality, durable concrete while contributing to environmental sustainability. As the industry continues to evolve, the smart integration of fly ash could pave the way for a more sustainable future in construction, balancing growth and ecological responsibility. As the world moves towards greener practices, the role of fly ash in concrete will undoubtedly become more prominent in the years to come, establishing a benchmark for sustainable building materials globally.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025