China Iron Oxide Pigments Manufacturer for Quality Color Solutions and Eco-Friendly Products

The Rise of Iron Oxide Pigments in China A Look into Manufacturing and Applications

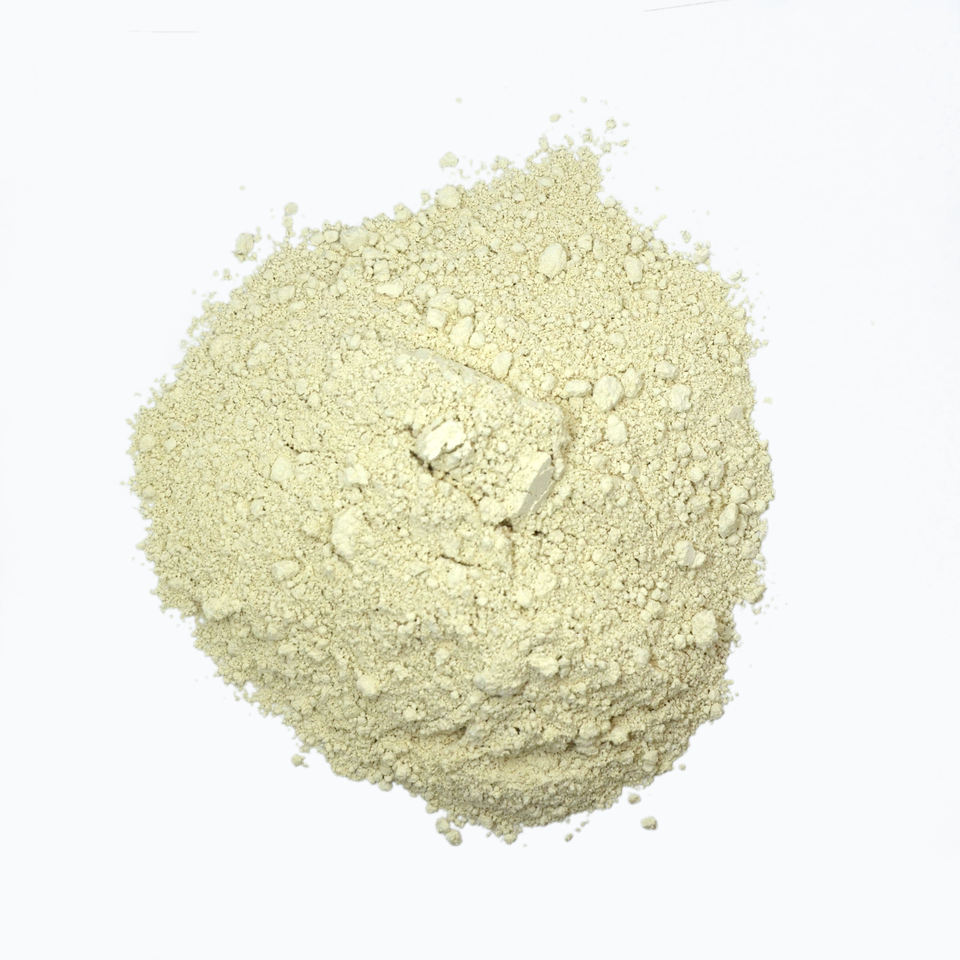

Iron oxide pigments have carved a significant niche in the global market, particularly with the increasing demand for high-quality, environmentally safe coloring agents in various industries. China, as one of the largest producers of these pigments, plays a pivotal role in the iron oxide pigment factory chain, supplying a vast array of products to both domestic and international markets.

Iron oxide pigments are derived from iron oxide compounds and are known for their stability, durability, and non-toxic characteristics. These attributes make them suitable for a wide range of applications including paints, coatings, plastics, construction materials, and even cosmetics. In recent years, the growth of industries such as construction, automotive, and consumer goods in China has significantly boosted the demand for iron oxide pigments.

The Rise of Iron Oxide Pigments in China A Look into Manufacturing and Applications

Moreover, the Chinese government has implemented various policies supporting the development of the chemical industry, including iron oxide pigments. Investments in infrastructure, research and development, and favorable trade policies have all contributed to creating a robust environment for manufacturers. This supportive climate has attracted both local and foreign enterprises to establish production facilities in China, further driving innovation and facilitating collaboration across the industry.

china iron oxide pigments factory

The color palette offered by Chinese iron oxide pigment factories is extensive. Iron oxide red, yellow, black, and brown pigments can be blended to achieve a variety of tones, which is especially beneficial for industries that demand customization. For instance, the construction industry utilizes these pigments in concrete, mortar, and asphalt, adding aesthetic value and increasing the longevity of these materials. Similarly, in the automotive sector, vibrant and durable colors derived from iron oxide pigments are used in vehicle coatings, enhancing both appeal and protection against environmental factors.

In addition to traditional applications, the rise of eco-friendly products has seen iron oxide pigments gaining popularity in the cosmetics industry. Many cosmetic manufacturers are opting for natural pigments derived from iron oxides, which provide safe and lasting color options without harmful effects on the skin. This shift towards sustainability aligns well with the global movement toward green manufacturing processes, with Chinese factories leading the way by developing non-toxic, eco-friendly formulations.

As global environmental concerns continue to rise, Chinese iron oxide pigment manufacturers are also adapting to meet stringent regulatory standards. Many factories are now focusing on producing pigments that are not only compliant with international safety standards but also contribute to sustainability efforts by reducing harmful emissions during production.

In conclusion, the landscape of iron oxide pigment manufacturing in China is marked by innovation and growth. With advanced production technologies, a supportive regulatory framework, and an ever-expanding range of applications, China is poised to maintain its status as a leading supplier of iron oxide pigments globally. The interplay of eco-friendliness and versatility in these pigments positions them favorably for continued demand across diverse industries. As businesses worldwide increasingly recognize the value of quality and safety, Chinese iron oxide pigment manufacturers are likely to thrive, fueling further advancements in the field.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025