2 月 . 11, 2025 13:23

Back to list

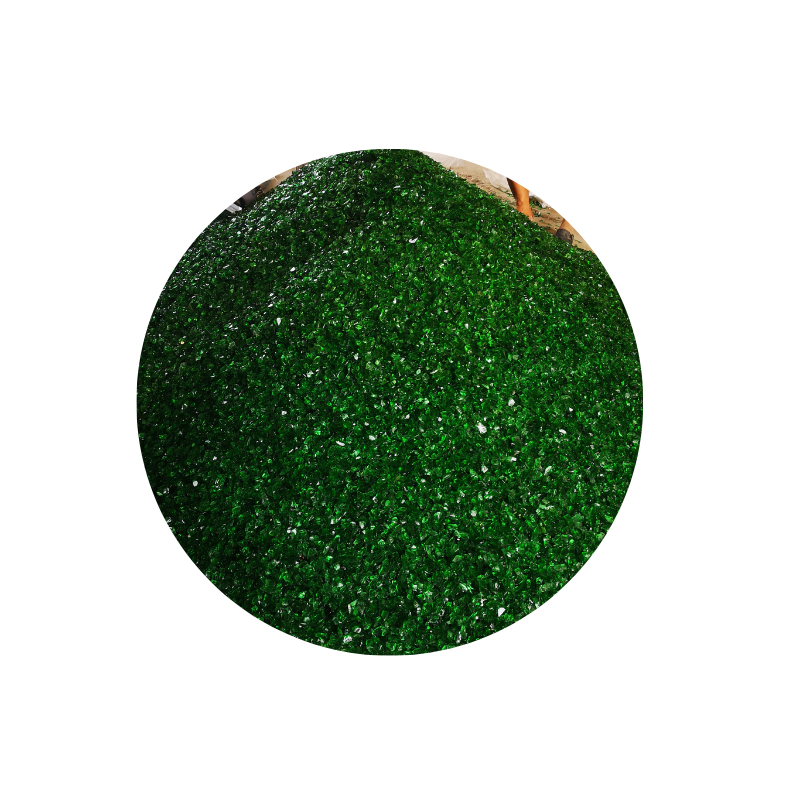

ceramsite sand

Ceramsite sand, an innovative and versatile material, has garnered attention for its myriad applications across industries. Known for its lightweight properties, high strength, and thermal insulation, ceramsite sand is increasingly replacing traditional materials. As someone who has extensively studied and utilized ceramsite sand, I can attest to its transformative impact on sectors like construction, agriculture, and metallurgy.

Apart from these industry-specific applications, ceramsite sand stands out for its environmental benefits. Manufactured from clay, shale, or fly ash, it is a sustainable choice that often uses recycled materials. Its production process has a lower environmental footprint compared to other aggregates. The long-term durability of ceramsite-based products extends their lifecycle, ensuring less frequent replacement and reduced waste. My involvement in several eco-friendly projects has highlighted ceramsite sand as an instrumental component in developing green infrastructure. Ceramsite sand's versatility also extends to water treatment processes. Its high adsorption capacity is used in filtering systems to remove contaminants and improve water quality. Research and tests I've conducted indicate that ceramsite sand effectively traps impurities, outperforming many conventional filter materials. Its application in municipal and industrial wastewater treatment facilities is growing, underscoring the material's crucial role in modern environmental management. In light of these experiences, ceramsite sand's role as a game changer in multiple sectors can't be overstated. Its multifunctional nature and inherent benefits present significant opportunities for innovation and advancement. Industry experts and materials scientists continue to explore new applications and developments involving ceramsite, seeking to harness its full potential. My continual experimentation with ceramsite sand consistently reaffirms its importance as both a product and a solution to complex industrial challenges. The future of ceramsite sand looks promising as industries worldwide increasingly prioritize sustainability and efficiency. Being lightweight yet robust, and versatile but environmentally friendly, ceramsite sand exemplifies the type of innovative material that meets modern demands. As we move towards more sustainable practices, the adoption and development of ceramsite sand are bound to play a pivotal role in shaping resilient and eco-conscious infrastructural solutions.

Apart from these industry-specific applications, ceramsite sand stands out for its environmental benefits. Manufactured from clay, shale, or fly ash, it is a sustainable choice that often uses recycled materials. Its production process has a lower environmental footprint compared to other aggregates. The long-term durability of ceramsite-based products extends their lifecycle, ensuring less frequent replacement and reduced waste. My involvement in several eco-friendly projects has highlighted ceramsite sand as an instrumental component in developing green infrastructure. Ceramsite sand's versatility also extends to water treatment processes. Its high adsorption capacity is used in filtering systems to remove contaminants and improve water quality. Research and tests I've conducted indicate that ceramsite sand effectively traps impurities, outperforming many conventional filter materials. Its application in municipal and industrial wastewater treatment facilities is growing, underscoring the material's crucial role in modern environmental management. In light of these experiences, ceramsite sand's role as a game changer in multiple sectors can't be overstated. Its multifunctional nature and inherent benefits present significant opportunities for innovation and advancement. Industry experts and materials scientists continue to explore new applications and developments involving ceramsite, seeking to harness its full potential. My continual experimentation with ceramsite sand consistently reaffirms its importance as both a product and a solution to complex industrial challenges. The future of ceramsite sand looks promising as industries worldwide increasingly prioritize sustainability and efficiency. Being lightweight yet robust, and versatile but environmentally friendly, ceramsite sand exemplifies the type of innovative material that meets modern demands. As we move towards more sustainable practices, the adoption and development of ceramsite sand are bound to play a pivotal role in shaping resilient and eco-conscious infrastructural solutions.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025