2 月 . 06, 2025 05:17

Back to list

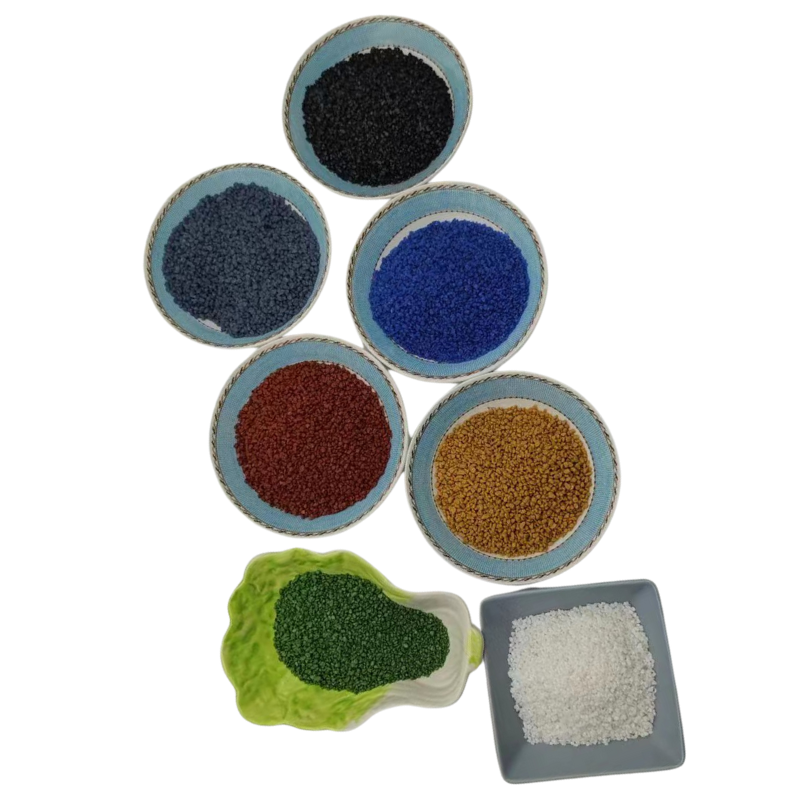

Concrete fly ash gray fly ash soil improvement add bulk fly ash for mixing plant

The integration of cement and fly ash in construction materials presents a remarkable opportunity for the construction industry to enhance the durability, sustainability, and efficiency of building projects. This innovative combination has rapidly gained traction due to its myriad benefits, extending far beyond conventional construction practices.

Real-world applications underscore the efficacy of cement and fly ash synergy. For instance, numerous infrastructure projects worldwide have successfully employed this mixture to extend the lifespan of structures while maintaining structural integrity. The Hoover Dam, an engineering marvel, used fly ash concrete to withstand high-pressure water flow and adverse weather conditions. In terms of expertise, it is crucial for construction professionals to understand the nuances of blending cement with fly ash. The amount of fly ash used can vary depending on specific project requirements and the type of fly ash available. Class F and Class C fly ashes are commonly used, each with distinct characteristics that influence their suitability for different applications. Knowing the origin and quality of fly ash is paramount in ensuring the desired performance outcomes. For those in the construction field new to this additive, consulting with materials scientists or civil engineers can provide invaluable insights. These experts can perform necessary tests, such as particle size analysis and pozzolanic activity assays, to tailor the cement-fly ash mix to exact specifications. Finally, the trustworthiness of this composite material is backed by numerous studies and certification standards that validate its performance. The American Society for Testing and Materials (ASTM) provides guidelines for using fly ash in concrete, ensuring its safety and effectiveness. Compliance with these standards is essential in certifying the quality and reliability of the end product. In conclusion, the adoption of fly ash in cement represents a forward-thinking approach to modern construction challenges. Its benefits extend beyond environmental gains to include enhancements in the longevity and robustness of structures. As the industry gravitates towards sustainable building solutions, the cement and fly ash combination offers a tangible pathway to greener, more resilient architecture. Implementing this blend with an understanding of its scientific and technical facets will undoubtedly continue to revolutionize the construction landscape.

Real-world applications underscore the efficacy of cement and fly ash synergy. For instance, numerous infrastructure projects worldwide have successfully employed this mixture to extend the lifespan of structures while maintaining structural integrity. The Hoover Dam, an engineering marvel, used fly ash concrete to withstand high-pressure water flow and adverse weather conditions. In terms of expertise, it is crucial for construction professionals to understand the nuances of blending cement with fly ash. The amount of fly ash used can vary depending on specific project requirements and the type of fly ash available. Class F and Class C fly ashes are commonly used, each with distinct characteristics that influence their suitability for different applications. Knowing the origin and quality of fly ash is paramount in ensuring the desired performance outcomes. For those in the construction field new to this additive, consulting with materials scientists or civil engineers can provide invaluable insights. These experts can perform necessary tests, such as particle size analysis and pozzolanic activity assays, to tailor the cement-fly ash mix to exact specifications. Finally, the trustworthiness of this composite material is backed by numerous studies and certification standards that validate its performance. The American Society for Testing and Materials (ASTM) provides guidelines for using fly ash in concrete, ensuring its safety and effectiveness. Compliance with these standards is essential in certifying the quality and reliability of the end product. In conclusion, the adoption of fly ash in cement represents a forward-thinking approach to modern construction challenges. Its benefits extend beyond environmental gains to include enhancements in the longevity and robustness of structures. As the industry gravitates towards sustainable building solutions, the cement and fly ash combination offers a tangible pathway to greener, more resilient architecture. Implementing this blend with an understanding of its scientific and technical facets will undoubtedly continue to revolutionize the construction landscape.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025