2 月 . 11, 2025 00:16

Back to list

iron powder manufacturer

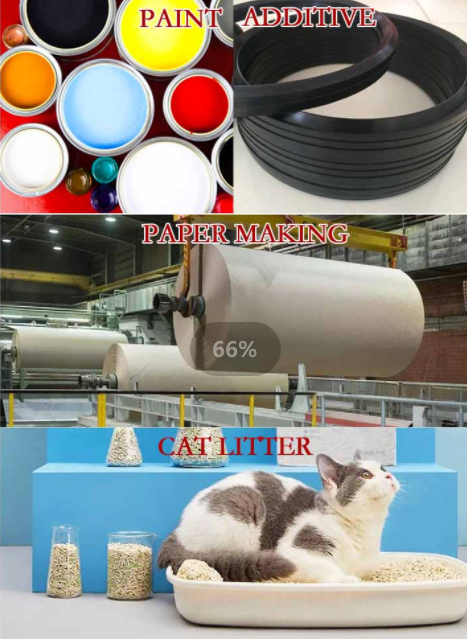

Navigating the world of calcium carbonate (CaCO3) powders requires insight into its production, applications, and the manufacturers who specialize in this field. As a mineral compound of immense versatility, calcium carbonate plays a critical role across various industries, its applications stretching from plastics to pharmaceuticals. Understanding the nuances of CaCO3 powder manufacturing not only provides a foundation of knowledge about its broader uses but also unveils the expertise encapsulated in its production processes.

The authority of a reputable CaCO3 powder manufacturer is further established through compliance with international standards and certifications. Adhering to ISO quality management systems and participating in sustainable extraction practices are keys to maintaining credibility in an industry that is as environmentally conscious as it is competitive. Transparency in sourcing, coupled with rigorous testing protocols for quality assurance, reinforces trustworthiness, a cornerstone of long-term partnerships with discerning clients. Manufacturers contribute valuable insights into the practical applications of CaCO3 in end-user industries. By providing technical support, they address specific challenges, ensuring that the chosen CaCO3 grade seamlessly integrates into the client's production process. This personalized guidance helps manufacturers optimize their formulations, reduce production costs, and enhance the quality of their final products. Moreover, the capability to innovate in response to market demand is crucial. Leading manufacturers are at the forefront of developing eco-friendly and sustainable calcium carbonate solutions. They recognize the shift towards biodegradable and recyclable materials, tailoring their offerings to align with this transition. This proactive approach not only exemplifies their commitment to sustainability but also positions them as thought leaders in a diversifying market. In summary, a distinguished calcium carbonate powder manufacturer is characterized by a wealth of experience, specialized expertise, established authority, and unwavering trustworthiness. These qualities reflect a commitment not only to the production of high-quality CaCO3 powders but also to the continuous pursuit of innovation and improvement. Businesses seeking to leverage the diverse capabilities of calcium carbonate can rely on these manufacturers as partners who understand their dynamic needs and are equipped with the knowledge and technology to meet them efficiently.

The authority of a reputable CaCO3 powder manufacturer is further established through compliance with international standards and certifications. Adhering to ISO quality management systems and participating in sustainable extraction practices are keys to maintaining credibility in an industry that is as environmentally conscious as it is competitive. Transparency in sourcing, coupled with rigorous testing protocols for quality assurance, reinforces trustworthiness, a cornerstone of long-term partnerships with discerning clients. Manufacturers contribute valuable insights into the practical applications of CaCO3 in end-user industries. By providing technical support, they address specific challenges, ensuring that the chosen CaCO3 grade seamlessly integrates into the client's production process. This personalized guidance helps manufacturers optimize their formulations, reduce production costs, and enhance the quality of their final products. Moreover, the capability to innovate in response to market demand is crucial. Leading manufacturers are at the forefront of developing eco-friendly and sustainable calcium carbonate solutions. They recognize the shift towards biodegradable and recyclable materials, tailoring their offerings to align with this transition. This proactive approach not only exemplifies their commitment to sustainability but also positions them as thought leaders in a diversifying market. In summary, a distinguished calcium carbonate powder manufacturer is characterized by a wealth of experience, specialized expertise, established authority, and unwavering trustworthiness. These qualities reflect a commitment not only to the production of high-quality CaCO3 powders but also to the continuous pursuit of innovation and improvement. Businesses seeking to leverage the diverse capabilities of calcium carbonate can rely on these manufacturers as partners who understand their dynamic needs and are equipped with the knowledge and technology to meet them efficiently.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025