Application

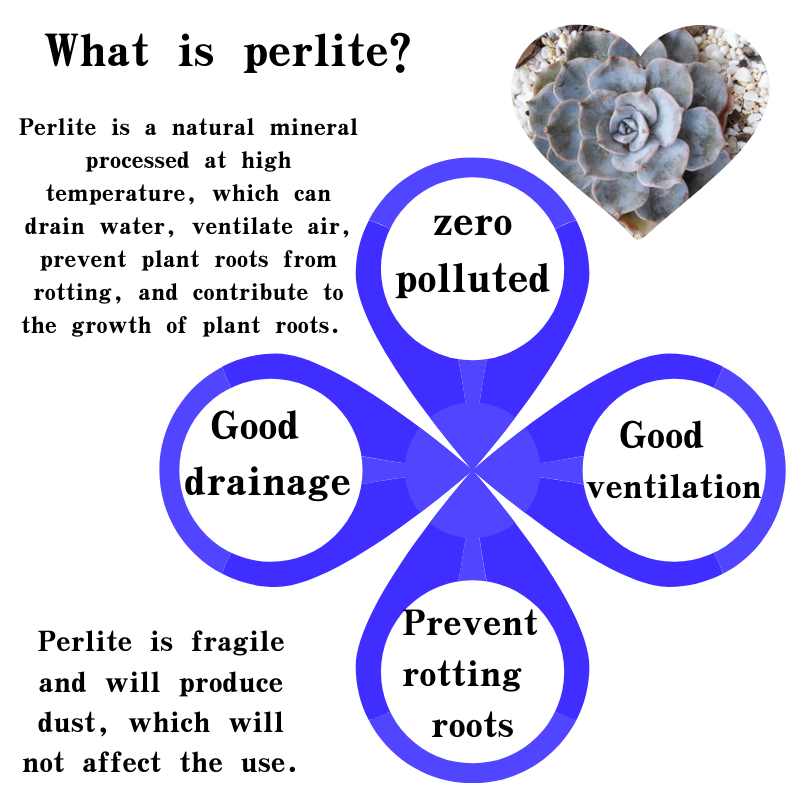

Perlite has been expanded to become a lightweight and multifunctional new material. It has the characteristics of light apparent density, low thermal conductivity,good chemical stability, wide use temperature range, small moisture absorption capacity, and non-toxic, tastless, fireproof, sound absorption, etc., and is widely used in a variety of industrial sectors.

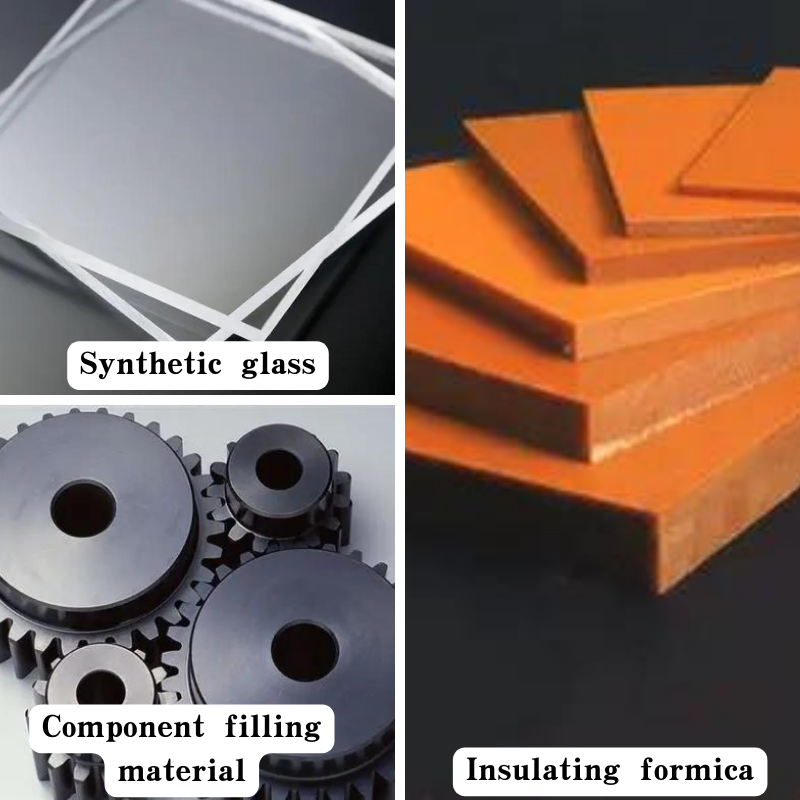

- 1.In the construction and manufacturing sector, it is used in lightweight stucco, concrete and mortar, insulation and ceiling tiles. It can also be used to build composite materials for sandwich structures or to make composite foams. Perlite filters are fairly common in beer before bottling. Small amounts of perlite are also used in casting, low-temperature insulation, and ceramics (as a clay additive).

- 2.Aquatic filtration Perlite is currently used in commercial pool filtration technology as an alternative to diatomaceous earth filters. Perlite is an excellent filter aid and is widely used as an alternative to diatomaceous earth. The use of perlite as a filtration medium is becoming more and more popular worldwide. There are several products on the market that provide perlite based filtration. A variety of perlite filters and perlite media are NSF-50 certified (Aquify PMF series and AquaPerl), a standard that standardizes water quality and technical safety and performance. Perlite can be safely disposed of by existing sewage treatment systems, although some pool operators choose to use sedimentation tanks or screening systems to separate perlite for separate treatment.

- 3.Agriculture In horticulture, perlite can be used as a soil amendment or alone as a medium for hydroponics or starting cuttings. When used as an amendment, it has high permeability and low water retention, helping to prevent soil compaction.

- 4.Cosmetics Perlite is used as an absorbent and mechanical exfoliator in cosmetics.

-

Certificates

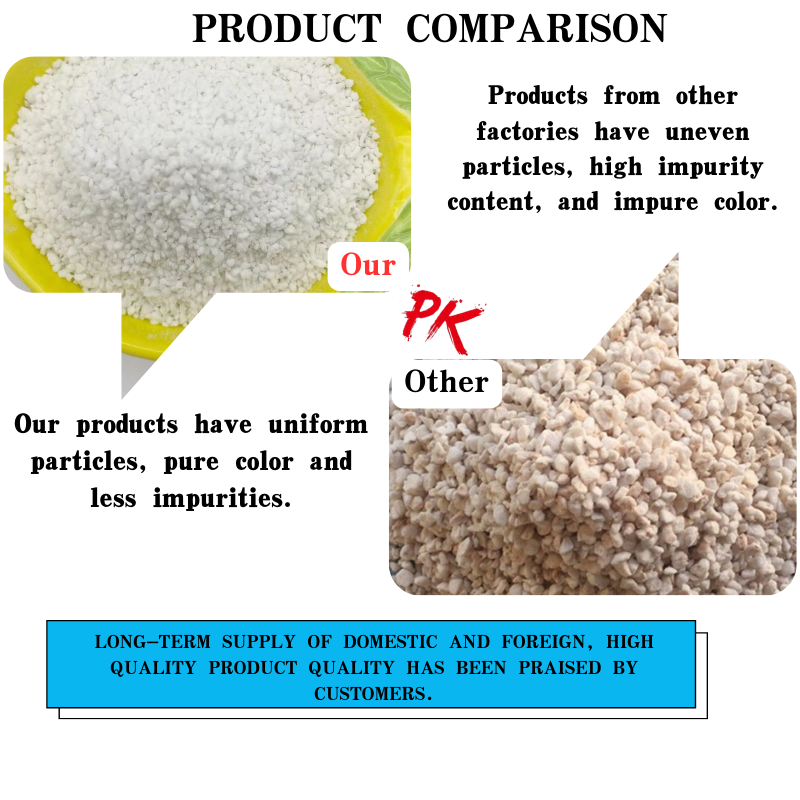

COMPARISON

Write your message here and send it to us